Ceramic printing is a unique method of introducing materials such as clay, glass and metal to printers. This exclusive technique can help people quickly and easily make unique ceramic pieces as well. It used to take an enormous amount of time and effort by skilled artisans, slaving away at their craft in order to make ceramic pieces. They then hand burnished the clay and used traditional methods of decoration to embellish them before they were fired. This has been done with ceramic production by cunning the use of technology such as Ceramic printing. As a result, the entire process has been simplified and accelerated for manufacturers to produce more beautiful designs that are hard to accomplish before.

Ceramic printers, on the other hand, has greatly expanded what designers can make. These printers could allow you to design complex and detailed pieces in a way that was difficult, if not impossible before. The printers spray inks onto ceramic surfaces, build layer by layer and provide full-color pictures / designs. This in return enables designers to design icons, textures or patterns with no anti-aliased soft edges. With the power of this technology, they can now manufacture excellent system for impressive everyone by their unique & detailed designs.

On the other hand, ceramic printing is very popular among designers and it can serve a wide range of industries. Most recently, it is used in the manufacture of home interior items as beautiful dishes and amazing vases. It is even employed in the automotive industry (automakers using it to produce actual car parts) and used for producin impoprtant electricial components. Besides, the level of precision in ceramic printers is key for producing good quality items with this material. These printers rely on dedicated software designed to enable engineers and designers alike as well fabricators a chance of being able reproduce the same design over, every time that is in order for each part produced to be made with exactness without any variation from one piece blowing others.

Recent years have seen a parallel increase in the speed and affordability of ceramic printing techniques. Modern printing techniques may create large numbers of pieces in a few hours, but will more time than sink handcrankers took weeks to produce same amount. This can be a huge benefit to manufacturers. It can be an environmentally friendly choice as well because ceramic printing uses less harsh chemicals and produces a lot less waste. Designers can also print only what they need, saving them from having to mass produce ceramics that might not sell. This helps cut down on wasted materials and unsold products.

New Industry CERAMIC PRINTING has brought about a paradigm change in the way products are made. And if you love home decor, even the most boring part of it will now get a facelift as we see that items like vases and bowls or tile having some neat detailed design. Conduct precision manufacturing of automotive and aerospace parts including sensors, turbine blades with the development of robust ceramic materials. For instance, ceramic printers can make dental implants and crowns that perfectly fit in the dentistry industry. Ceramic printing technology is also employed by the electronics industry to manufacture small and necessary parts, such as capacitors or sensors used in different devices.

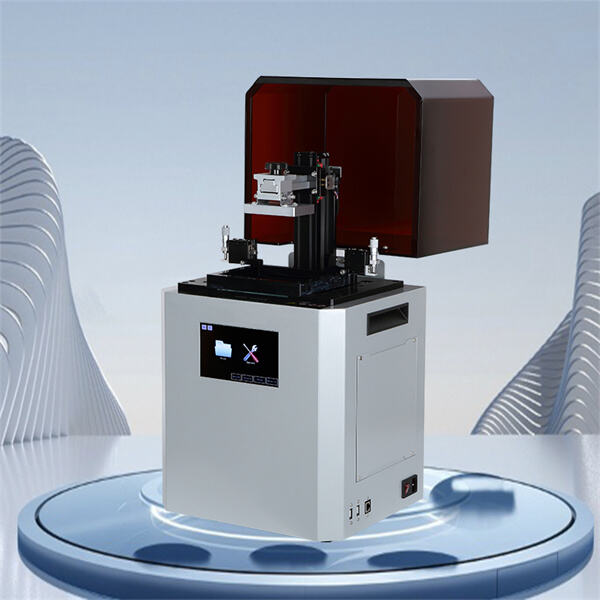

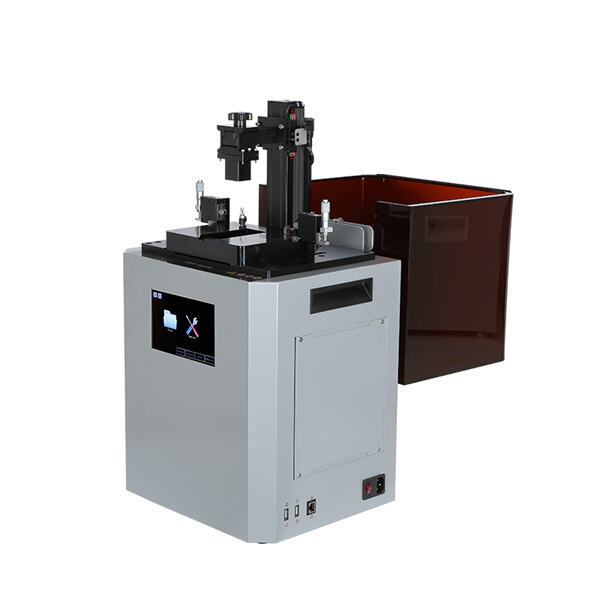

Shenzhen 3KU Technology and Science Co., LTD is established in the year 2014. Within just a few years of developing and marketing, our brand 3KU is well-known by 3d printer fans and users. We offer a complete technical support, printing technology, after processing, casting methods and a Ceramic printer. We provide professional technology and customized services, solving casting and printing issues across different fields.

Since 2012 our founder has been working on Ceramic printer, ranging all the way from FDM to DLP, SLA. He believes in "3d technology that will bring about another industrial revolution"! We try our best to provide more support for technical and service issues for those who are 3D Printer fans and have a strong support for us! We provide considerate support and respond quickly to market demands.

Our Ceramic printer have been utilized in a variety of industries, including Jewelry, Temples Dentals, Ceramics and more. Our custom services are ideal. The customized services include the appearance design, customized logo, software design, more functionality and the personalized packaging. We provide our customers with 3D printers at the most affordable prices, and with the highest quality, utility and efficiency.

Ceramic printer on an original layout and design, in particular our excellent research team, our printers are used across a range of sectors, like Dental cast and crown, Jewelry cast, Garage Kit, Precise Molding, ect. We offer free samples. We can print stl documents on our printers and show you how they work and the results before you purchase.

Copyright © Shenzhen 3KU Technology and Science Co., LTD. All Rights Reserved Privacy Policy Blog