- Overview

- Inquiry

- Related Products

Specifications:

|

Model |

Prism HR25 |

|

Technology |

4K DLP 3840x2160 Pixels |

|

FormingMethod |

Upside-down, pull-up,molding |

|

Resin |

Ceramic(Al2O3, AlN, ZrO2, SiO2, Si3N4, SiC, TCP, HA, Bioglass and similar) |

|

SupportFiles |

STL OBJSLCPR3 |

|

Forming Size |

96x54X100mm |

|

Resolution |

25μm |

|

LightUniformity |

>95% |

|

Accessibility |

Reciprocating auxiliaryleveling scraper, height adjustable |

|

Lightenergydensity |

Parameteradjsutable, 0-50 mw/cm² |

|

Volume of loaded material |

5-30ml |

|

Vat Tank Heating |

Yes, 40-45 degree |

|

Layer thickness |

10-100um |

|

Machine Size |

450 x 360 x 800мм |

|

Weight |

NW:30KG |

|

Warranty |

oneyear |

Quick Detail:

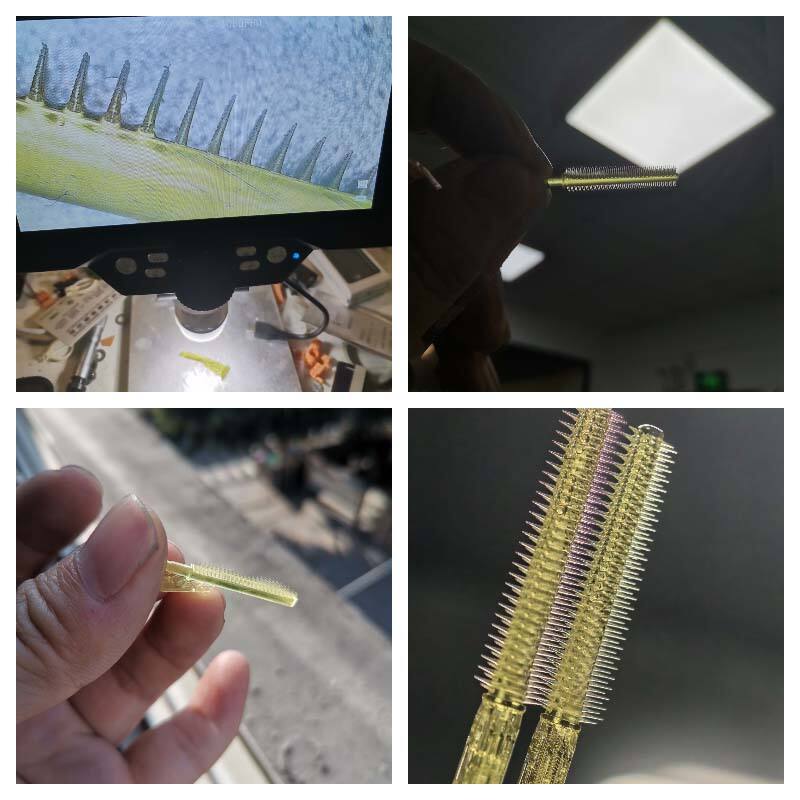

1. Pull-up DLP 3d Printer

2. Multi functional composite materials Bio-material Ceramic slurry material research and development test

3. High Resolution 5um 10um 15um 25um 35um Micro Nano Resin 3d Printer

Applications:

1. Ceramic slurry material research and development test and production

2. Bio-material printing testing and producing

3. Multi functional composite materials testing and producing

Competitive Advantage:

In order to improve the efficiency of material research and development, this series of printers has added many unique functions:

1. No need to connect to a computer and supports U disk/Wi-Fi offline printing.

2. The touch screen can directly modify and save printing parameters.

3. Different printing modes can be directly switched through parameters.

4. Supports rapid curing testing and can measure multiple sets of parameters in a short time.

5. Printing parameters can be modified in real time during the printing process.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

SL

SL

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

BE

BE

IS

IS

MY

MY