Bạn có muốn thực hiện một số dự án tuyệt vời theo cách thú vị không? Bạn đã bao giờ nghĩ đến việc sử dụng máy in 3D chưa? Máy in 3D là một chiếc máy tuyệt vời có thể tạo ra các đối tượng ba chiều. Vì vậy, hãy tưởng tượng rằng những đối tượng này có chiều cao, chiều rộng và chiều sâu giống như mọi thứ bạn có thể chạm hoặc nhìn thấy. Nhưng điều đó hoạt động như thế nào trong thực tế? In 3D cơ bản sử dụng các vật liệu đặc biệt gọi là 'nhựa' được叠加 lớp lên lớp để tạo thành đối tượng mà bạn có trên camera của mình.

Có một loại nhựa cụ thể đang khiến ngành công nghiệp xôn xao -- đó là nhựa gốm. Những vật phẩm như vậy được làm từ một loại nhựa đặc biệt có khả năng cứng lại thành gốm. Gốm sứ -- được làm từ đất sét. Khi đất sét được nặn hình và đặt vào lò nung cực kỳ nóng, nó sẽ cứng lại. Có nhiều loại đồ vật bằng gốm khác nhau mà chúng ta có thể thường xuyên thấy được sử dụng để trang trí trong nhà, chẳng hạn như bát đĩa, tô hoặc lọ hoa.

Một loại resin gốm phù hợp cho in 3D. Không phải tất cả các loại resin in 3D đều giống nhau. Những loại resin này được tạo ra để bền lâu hơn và cứng cáp hơn so với các loại khác. Nó cũng có thể được định hình thành nhiều dạng khác nhau, điều mà tôi nghĩ là khá tuyệt! Điều đó có nghĩa là bạn có thể sản xuất ra những sản phẩm có độ phân giải cao và thẩm mỹ từ resin gốm.

Điểm tuyệt vời của nhựa gốm là nó có thể tạo ra một số bản in chất lượng nhất trong lĩnh vực gốm sứ trong khi chi phí thấp hơn so với các phương pháp truyền thống. Nó làm được điều này bằng cách in 3D gốm sứ, thay vì làm hoàn toàn thủ công như trước đây, điều đó sẽ mất nhiều thời gian hơn và kém chính xác hơn. Loại nhựa này, loại nhựa hiện đại và tiên tiến này được sử dụng bởi nhiều máy in 3D khác nhau để sản xuất những bản in thu hút ánh mắt.

Một lý do tuyệt vời khác để sử dụng nhựa gốm là cơ hội mà nó mang lại cho bạn để thể hiện sự sáng tạo và tài năng của mình. Mỗi ý tưởng hoặc khái niệm được tạo ra đều có thể thực hiện được nhờ vào máy in 3D và nhựa gốm, ví dụ như bạn có thể muốn thiết kế và tạo ra chiếc lọ hoa riêng của mình, thứ gì đó độc đáo với hình dạng đặc biệt hoặc trang sức gốm phù hợp với phong cách của bạn. Có rất nhiều khả năng để bạn thể hiện bản thân theo nhiều cách khác nhau!

Có nhiều loại nhựa khác nhau được sử dụng cho in 3D, và mỗi loại đều có những đặc điểm riêng biệt. Một số rất cứng và giòn. Hơn nữa, một vài loại nhựa chịu nhiệt tốt và không bị mềm hay biến dạng khi tiếp xúc với nhiệt độ cao. Nhựa gốm dễ vỡ nhưng nó sở hữu tất cả các tính chất mà bạn cần để tạo ra những bản in gốm đẹp mắt và bền bỉ //!

Dựa trên nhựa gốm dành cho máy in 3D và xây dựng, đặc biệt nhờ đội ngũ nghiên cứu xuất sắc của chúng tôi, các máy in của chúng tôi được ứng dụng trong nhiều lĩnh vực khác nhau như đúc răng và mão răng nha khoa, đúc trang sức, bộ phụ tùng garage, khuôn chính xác, v.v. Chúng tôi cung cấp mẫu miễn phí. Bạn có thể gửi cho chúng tôi các tệp STL, và chúng tôi sẽ in bằng máy in của mình để minh họa cách thiết bị vận hành cũng như kết quả đạt được trước khi bạn mua hàng.

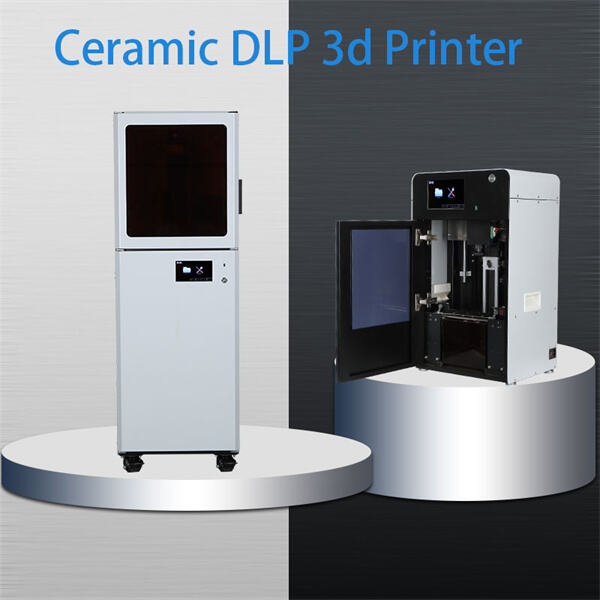

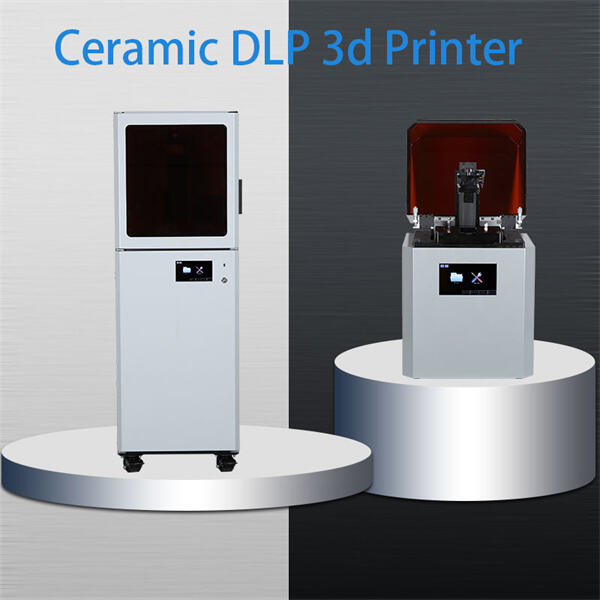

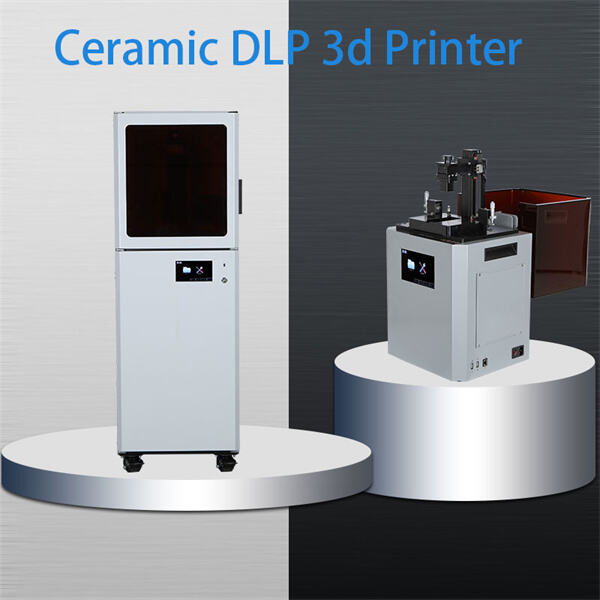

Người sáng lập công ty chúng tôi đã làm việc trong lĩnh vực máy in 3D từ năm 2012, bắt đầu từ các công nghệ FDM, DLP và SLA. Ông tin rằng: "Công nghệ 3D sẽ khơi dậy một làn sóng mới về nhựa gốm dành cho máy in 3D"! Chúng tôi nỗ lực hết sức nhằm cung cấp thêm nhiều dịch vụ và hỗ trợ kỹ thuật cho những người yêu thích máy in 3D — những người luôn ủng hộ chúng tôi mạnh mẽ! Chúng tôi có gói đóng gói dạng tháp với mức giá cạnh tranh nhất. Chúng tôi mang đến dịch vụ thân thiện và có khả năng phản ứng nhanh trước các xu hướng thị trường.

Các máy in của chúng tôi đã được sử dụng trong nhiều ngành công nghiệp khác nhau như trang sức, nhựa gốm cho máy in 3D, gốm sứ và nhiều lĩnh vực khác. Dịch vụ tùy chỉnh của chúng tôi rất phù hợp. Chúng tôi cung cấp đa dạng dịch vụ tùy chỉnh, chẳng hạn như thiết kế bao bì kèm phần mềm, logo, bao bì và nhiều hơn thế nữa. Chúng tôi cung cấp cho khách hàng các máy in 3D với mức giá rẻ nhất cùng chất lượng, tính năng và hiệu suất cao nhất.

Công ty TNHH Công nghệ và Khoa học Thâm Quyến 3KU được thành lập năm 2014. Chỉ trong vài tháng ngắn ngủi, 3KU đã trở thành một thương hiệu nổi tiếng trong giới người dùng nhựa gốm cho máy in 3D và những người yêu thích thương hiệu này. Chúng tôi cung cấp đầy đủ hỗ trợ kỹ thuật, công nghệ in, xử lý hậu kỳ, phương pháp đúc và bảo hành trọn đời. Chúng tôi có thể cung cấp công nghệ chuyên sâu bậc cao cùng các dịch vụ tùy chỉnh, giải quyết các vấn đề liên quan đến đúc và in ấn trong nhiều lĩnh vực khác nhau.

Bản quyền © Shenzhen 3KU Technology and Science Co., LTD. Tất cả các quyền được bảo lưu Chính sách bảo mật Blog