هل سمعت عن الطباعة ثلاثية الأبعاد؟ إنها عملية مثيرة للغاية باستخدام آلة خاصة تبني جسمًا طبقة بطبقة من المواد مثل البلاستيك أو المعدن. فكر في ما يمكنك تطويره باستخدام تحرير المتجهات بهذه الطريقة؟ يمكنك حتى إنشاء أشياء مثل الحلي التي يمكنك طباعتها باستخدام الطباعة ثلاثية الأبعاد! ومع ذلك، قد تسأل الآن، كيف أحصل على قطعة مطبوعة ثلاثية الأبعاد لأرتديها وأظهرها كحلي؟

ولكنك لست تقوم بصنع حلي حقيقية عند طباعة تصميم الحلي باستخدام الطباعة ثلاثية الأبعاد. إنها قطعة مزيفة، مصنوعة لتبدو وكأنها حقيقية. هذا القرن الوهمي عادة ما يُصنع من مواد مثل البلاستيك أو الشمع. الشجرة العارية هي فقط حتى يمكن استخدام القلم والحبر لإعادة إنتاجها في دفترك، لكن الصب والتوجيه هما طريقتان لتحويل هذا المعدن إلى حلي حقيقية يمكنك ارتداؤها! الصب من ناحية أخرى هو عملية تتضمن صب معدن ذهبي أو فضي لامع وبارد في نوع من القوالب. إذن القالب هو قالب للشكل الذي تريد أن يكون عليه قطعة حليك. ثم يتم ملؤه بسائل يتحول إلى صلب، مما يخلق نسخة طبق الأصل لحليك داخله. بعد ذلك، يُصب المعدن المنصهر في القالب ويملأ المساحة الفارغة ليأخذ شكل قطعة الحلي.

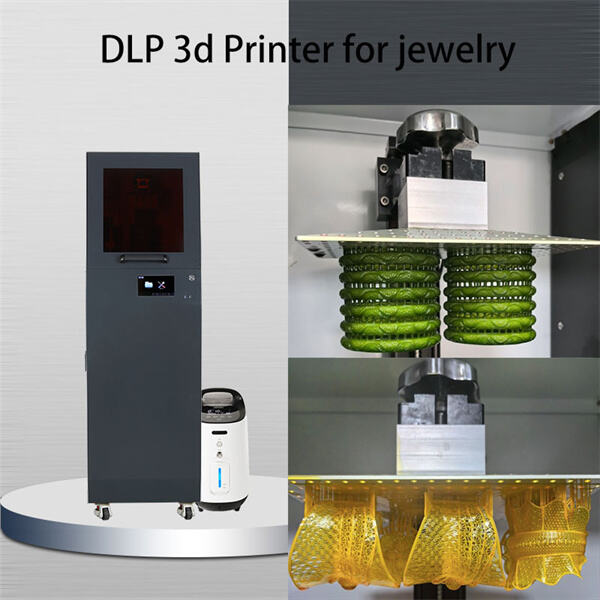

ابدأ في إنشاء تصميم المجوهرات الخاصة بك باستخدام الحاسوب. يجب أن تحصل على التصميم الصحيح لأن أي خطأ صغير ترتكبه سيظهر في المنتج النهائي. وعندما تقوم بمراجعة دقيقة لتصميمك وتشعر بأنه يبدو مثاليًا، ينتقل البعد التالي إلى طباعة مثل هذه الملفات ثلاثية الأبعاد باستخدام مواد تقليدية تعتمد على الشمع أو الراتينج بواسطة طابعة ثلاثية الأبعاد خاصة. الشكل الذي يتم فيه تمثيل تصميمك سيكون نفسه تمامًا، ولكن مع شمع أو راتينج. النموذج الأولي المبدئي.

تُستخدم نماذج الطباعة ثلاثية الأبعاد بشكل شائع جدًا في عملية الصب لأسباب عديدة. الميزة الأولى هي أنها ستوفر لك كميات هائلة من الوقت. المجوهرات التقليدية يوشينو: في إنشاء المجوهرات التقليدية، بما أن الحلاق يجب أن يصنع الجيلاتي اليدوي على عجل خلال أيام دون ممارسة خالية من العيوب، يتم استخدام الدليل السككي بدون فواصل. ولكن الطباعة ثلاثية الأبعاد تسمح للحلاق بإنشاء شيء ما على الكمبيوتر خلال دقائق. بمعنى آخر، أقل انتظارًا لك ومزيد من الاستمتاع بنهاية المجوهرات الجديدة الخاصة بك!

الطباعة ثلاثية الأبعاد أكثر دقة مقارنة بصناعة المجوهرات يدويًا. الأخطاء تحدث بسهولة من قبل البشر، لكن ليس بهذه الشكل كل مرة تقوم فيها الطابعة ثلاثية الأبعاد بإنشاء قطعة واحدة. مما يعني أنك تحصل على قطعة مجوهرات خالية من العيوب والتي تشبه تصميمك. هذا أيضًا يفتح فرص جديدة للمصممين لتصبح أكثر إبداعًا مع تصاميمهم (خاصة تلك التي تكون صعبة أو تتطلب الكثير من العمل).

الحلي المطبوعة بتقنية 3D - متعة حقيقية للعمل معها. يمكنك صنع أي بصمة يمكنك تخيل طباعتها بثلاث أبعاد. يمكن أن تطلق العنان لإبداعك! بالإضافة إلى ذلك، يمكنك أيضًا صنع حلي تناسب مقاساتك الشخصية بشكل مثالي. في الماضي، كانت هناك أحجام خواتم تقليدية لا تناسب الجميع. ومع ذلك، باستخدام تقنية الطباعة ثلاثية الأبعاد، يمكن أن يكون الخاتم مصممًا ليتناسب تمامًا مع يدك!

على الرغم من أنها تستغرق وقتًا قليلاً أكثر، فإن صب الحلي المطبوعة بتقنية 3D ممتاز لتصميمات الملابس الإبداعية الفريدة من نوعها. يمكنك طباعة تصميم معين مرة واحدة، ثم استخدامه لصنع عدد غير محدود من القطع كما تخطر على بالك. بهذه الطريقة يمكنك إعادة إنشاء التصميم المخصص مرارًا وتكرارًا. وأيضًا، بفضل الطباعة ثلاثية الأبعاد، يمكنك تجربة تصميم (أو عدة تصاميم) لمعرفة كيف يبدو قبل البدء في العمل عليه بالمعدن.

لقد تم استخدام طابعاتنا في مختلف الصناعات، مثل صناعة المجوهرات، والصبّ باستخدام تقنية الطباعة ثلاثية الأبعاد للمجوهرات، والفخار، وغيرها. وخدماتنا المخصصة مثالية تمامًا. ونقدّم مجموعةً واسعةً من الخدمات المخصصة، مثل تصميم العبوة جنبًا إلى جنب مع البرمجيات، والشعار، والعُلب التغليف، وغيرها الكثير. كما نقدّم لعملائنا طابعات ثلاثية الأبعاد بأقل الأسعار، وأعلى جودةٍ وكفاءةٍ وفعاليةٍ.

استنادًا إلى خبرتنا في مجال الصبّ باستخدام تقنية الطباعة ثلاثية الأبعاد للمجوهرات والهندسة، وبخاصةً بفضل فريق بحثنا المتميز، تُستخدم طابعاتنا في قطاعات متنوعة، مثل الصبّ السني وتلبيس التيجان، وصبّ المجوهرات، وصناديق أدوات المرآب (Garage Kit)، والقالَبات الدقيقة، إلخ. ونقدّم عيّنات مجانية. ويمكنك تزويدينا بملفات الـ STL، وسنقوم نحن بطباعتها باستخدام طابعاتنا، لإظهار طريقة عملها والنتائج التي تحقّقها قبل أن تقوم بالشراء.

تأسست شركة شينتشن 3KU للتكنولوجيا والعلوم المحدودة في عام 2014. وخلال بضعة أعوام من التسويق والتطوير، أصبح علامتنا التجارية «3KU» معروفةً جيدًا لدى عشّاق الطابعات ثلاثية الأبعاد والمستخدمين. ونوفر دعمًا فنيًّا كاملاً، وتكنولوجيا طباعة متقدمة، وخدمات ما بعد الصب، إضافةً إلى صب المجوهرات المطبوعة ثلاثيّة الأبعاد، وضمانًا مدى الحياة. كما نقدّم تكنولوجيا احترافية وخدمات مخصصة لمساعدتكم في حل مشكلات الصب والطباعة عبر مجموعة واسعة من المجالات.

بدأ مؤسس شركتنا العمل على الطابعات ثلاثية الأبعاد منذ عام 2012، بدءًا من تقنيات FDM وDLP وSLA. وهو يؤمن بأن «صب المجوهرات المطبوعة ثلاثيّة الأبعاد سيكون المحفّزَ لثورة جديدة في القطاع الصناعي». ونسعى جاهدين إلى تقديم دعمٍ فنيٍّ وخدميٍّ أكبر لأصحاب الشغف بالطابعات ثلاثية الأبعاد الذين يقدّرون دعمنا القوي لهم! ونوفر خدمةً ودودةً وسريعة الاستجابة لتغيرات السوق.

حقوق النسخ © شركة شنتشن 3KU للتكنولوجيا والعلوم المحدودة. جميع الحقوق محفوظة سياسة الخصوصية المدونة