If you use 3D printing quite a lot, you may possibly have run into both DLP and SLA before. However, what does this all really signify? But which are better for your projects? This article will look at the differences between DLP and SLA printing. Their strengths and weaknesses are examined separately — so, based on those analyses, we recommend what each model is best suited to.

DLP and SLA are two different types of light processing 3D printing techniques, which stereotype the liquid resin into a solid model. All this work is done at layer by layer, which i found very fascinating! DLP — Digital Light Processing, SLA — Stereolithography. The difference between these methods is their use of light to cure or harden the resin.

DLP printing on the other hand, makes use of a digital projector to shine light across an entire layer at once. That way, the entire layer can solidify simultaneously. THIS IS WHAT MAKES DLP PRINTING SO MUCH FASTER THAN SLA. On the other hand, SLA passes a laser on the exterior of each layer to outline its shape. This specific method enables SLA to produce shapes intricately and highly complex. On the other hand, DLP can be slightly less accurate than SLA. This is because the light can be bent a bit when going through the resin, which could impact its final shape.

Like we said before, the DLP printing is in general faster than SLA one. If you need to generate large numbers of parts very quickly, this speed can be a major draw. Suppose you are doing a project of small pieces and it consumes too much time, DLP could be helpful as well. SLA is generally better to create shapes with very fine details in them. More sophisticated parts: The laser used in SLA printing enables much more precise and intricate shapes — making it ideal for items that need to meet exact sizes.

A less fundamental difference between DLP and SLA processes is the types of resin each prints with. Because SLA printing can work with a more diverse range of resins, offering flexible resin and high-strength engineering resin that stands up to heat and pressure. This range of materials is what makes SLA an ideal selection for robust parts. Like for fitting that need to accommodate much strain on it, in this case SLA is a good choice.

In contrast, DLP printing usually has a more limited selection of resins intended for convenience and fast curing times. While they are not as strong or heat resistant as some SLA resins, for many applications that do not require exceptional durability and high temperatures capabilities these work pretty well. If you are working on decorative items or models for instance, DLP resins could be a better choice.

Generally, DLP printing is a better option for you if: You are looking to make many parts quickly and there is no requirement of strong or high detailed parts. But if you are making parts that require accuracy or precision, SLA printing will be a better fit for your application and offer more choice of material.

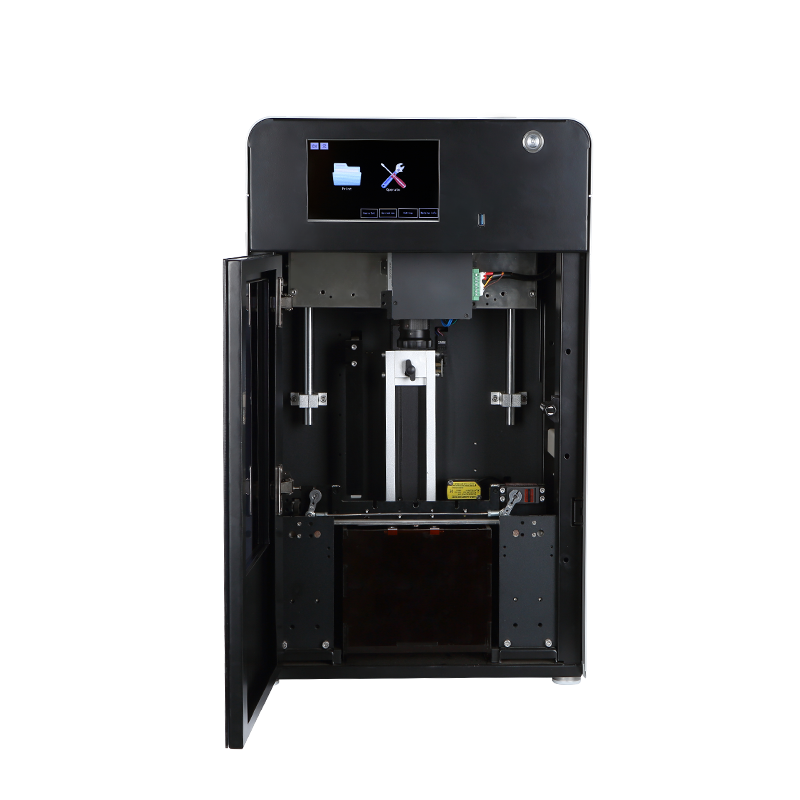

Our printers have been used across a dlp and sla of industries, such as Jewelry, Temples Dentals, Ceramics etc.. We offer customized services that are perfect. The services that we customize include the outlook design, the customized logo, the software design, more functionality and the customized packaging. We provide our customers with 3D printers at the most affordable prices with high quality, utility and efficiency.

dlp and sla is established in the year 2014. Within just a few years of developing and marketing, our brand 3KU is known well by 3d printer lovers and users. We offer a wide range of technical support that includes printing technology, post-processing, casting techniques, and a lifetime warranties. We provide highly skilled support and technology. We we can resolve printing and casting issues in various areas.

dlp and sla founder of our company has been working on 3D printers since 2012, beginning with FDM, DLP, SLA. He believes that "3d technology will lead another industrial revolution"! We try our best to provide better service and technical assistance to 3D printer lovers, who we support and are steadfastly in our support! We provide the most competitive tower packaging. We offer a friendly service and can react quickly to market shifts.

Our printers, which are based on a unique design, dlp and sla, and most importantly our outstanding team of researchers can be found in many industries like Dental Casts and crowns, Jewelry castings, Garage Kits, Precise moldings, and more. We offer free examples. You can send us stl files, and we print using our printers to show how it operates and what the results are before you purchase.

Copyright © Shenzhen 3KU Technology and Science Co., LTD. All Rights Reserved Privacy Policy Blog