Quality jewelry is not something that you have made every day, and with training to be competitive in a manufacturing setting. It is a fascinating process! This is if you want to jewelry making of any type so-to-speak the very crucial step of molding. A mold is basically a form for shaping the jewelry we wear. Molds are essential to the creation of intricate and visually stunning jewelry.

Until now, casting would have been a considerable amount of work and time. The design of each mold was shaped by hand which could often take many hours or even days for a skilled craftsman. However, with more up-to-date technology like 3D printers making molds has become much less laborious and time-consuming!

A 3D printer allows designers to do on molds what they can already create for jewelry shapes. TrackingBack on my day, when they designed airplanes in pencil and using special software that let them create 3D models of their designs. The 3D printer would later turn those models into actual molds which can be used for the pouring of metal to create jewelry. It is quick and efficient, helping the designers in actualizing their ideas.

However, a 3D printer allows the designers to produce molds much quicker and in more convenient way. The best part being they can spend more time doing what they love, creating their jewelry over making the molds. When these design experiments now provided results less than 24 hours later, designers could see their ideas come to life faster.

3D printing can also be more cost effective than previously available methods of mold making. One of the reasons is that 3D printers require less material than conventional methods. They produce molds of the same quality without using resources. And is also environmentally more friendly!

From rings to necklaces, bracelets and earrings — 3D printed molds can form all sorts of jewelry! There are different fashionable materials to pick from when its comes making jewellery Gold and silver of which makes it even more lovable by many who opt for lovely touch-ups with beautiful combinations.

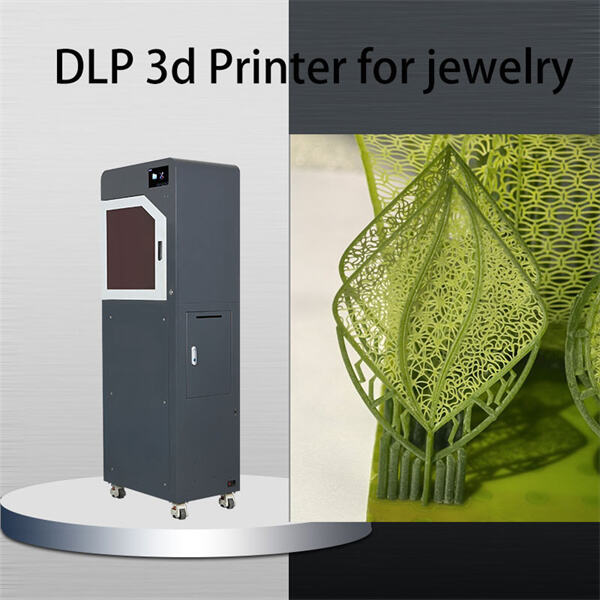

Jewelry molds with 3D printers, that is quite a game changer for the jewelry world. Creates detailed and intricate molds that are nearly impossible to make by hand. Not only does this technology save time and funds but it also makes sure that the final pieces end up looking as flawless as their molds.

3d printer for jewelry molds is established in the year 2014. Within just a few years of developing and marketing, our brand 3KU is known well by 3d printer lovers and users. We offer a wide range of technical support that includes printing technology, post-processing, casting techniques, and a lifetime warranties. We provide highly skilled support and technology. We we can resolve printing and casting issues in various areas.

Our printers, based on a unique design, structure, and most importantly our highly skilled team of 3d printer for jewelry molds, are used in various industries like Dental Casts and crowns Jewelry casts, Garage Kits, Precise Moldings, and more. We support the provision of free tests. We are able to print stl files on our printers and show you how they function as well as the results before you purchase.

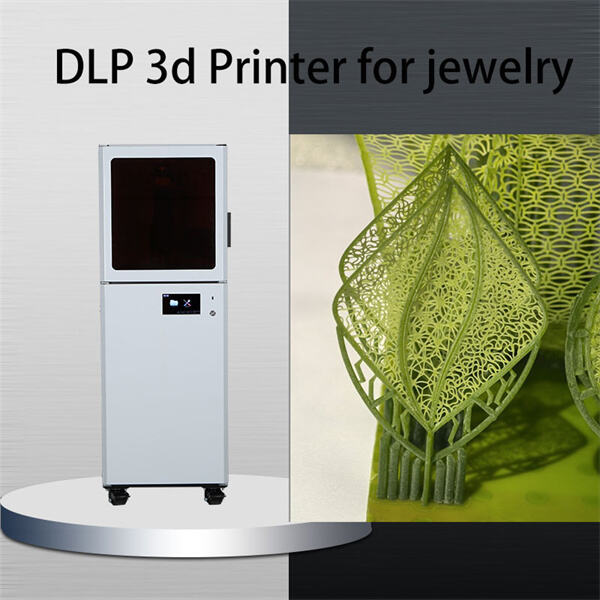

Our printers are applied across a range of industries, such as 3d printer for jewelry molds, Temples, Dentals, Ceramics, etc.. We offer a wide range of customized services. We provide a broad range of customized services, including the design of the packaging along with the software, branding, packaging and many other functions. We provide our customers with 3D printers for the cheapest prices with high quality, functionality and efficacy.

The founder of our company has been working on 3D printers since 2012, starting with FDM, DLP, SLA. He is convinced that "3d technology will lead another industrial revolution". We strive to provide more 3d printer for jewelry molds and technical support to 3d printer enthusiasts who believe in us strongly! We have the best priced tower packaging. We provide considerate support and quickly respond to market needs.

Copyright © Shenzhen 3KU Technology and Science Co., LTD. All Rights Reserved Privacy Policy Blog