Ever heard of 3d printing? It is a particular printing that lets you build things out of 3D, so the objects can dominate and look real, practically living! For example, molds for jewelry can be made with a 3D printer. Molds: These are crucial, as they mold the shapes of your jewelry pieces. In the process of 3D printing Jewelry Molds? Let's explore More and know How does it work!

Jewelry Molds are tools used to cast reproductions of jewelry articles. Jewelry molds are like cookie cutters for jewelry! They allow identical shapes to be cut time and again. Molds can be made of a wide variety of materials, such as metal or plastic (and now - 3D printing!) These are created to shape with specific designs which is much more exciting for jewelry makers as anything they can design, however detailed or precise, it can be manifested into reality using 3D printing.

Before 3D printing was invented, jewelry molds took a great deal of time and money. It was also very hard to do! Making the molds required a different set of skills than casting jewelry. Fast forward a decade or so and the jewelry industry has undergone seismic shifts, mostly attributed to 3D printing. This has reduced cost and time to make molds. Anyone can print their mold even if it is only a beginner. This technology has given a lot to the designers and artists, making them more creative like they never been before!

3D Printing allows jewelry designers to create intricate, beautiful designs which were impossible or very difficult. They can produce unconventional shaped jewelry pieces It is for this very reason that the jewellery items can be designed to appear extremely exclusive! If you choose 3D printing, it would also help designers to hand craft unique pieces for you. How cool would it be to own a jewelry piece that was suitable made for you, explicitly your favorite colors or shapes! This allows for jewelry to be personalized and makes the production of every piece ever more unique, as each is custom made.

3D Printed Molds for Jewelry: Why They Make Sense For one, they are far less expensive to produce than traditional molds. That would mean that jewelry would be cheaper, which in turn meant more people could afford it. Isn’t that great? They are also a whole lot faster to make so jewelry won't take an age in comparison. Because 3D printing enables more intricately designed pieces, jewelry can be made even more unique. And lastly, using 3D tetrahedron printed molds helps in generating less waste as only the material required to create specific mold is used. This is the best for our planet!

There are so many ideas for 3D printed jewelry molds! Suspension Molds: 3D printing will allow suspension molds to be built in any shape or form. This makes it capable of being used formyriad sizes and shapes of jewelry making. Go handcrafted with jewelry designed after nature, animals or your best-loved cartoon characters! How cool is that? They are made using 3D printers and in custom sizes as well, so that they fit all on anyone. And it implies that all individualized and stereotypical jewelry are right up this street of yor.

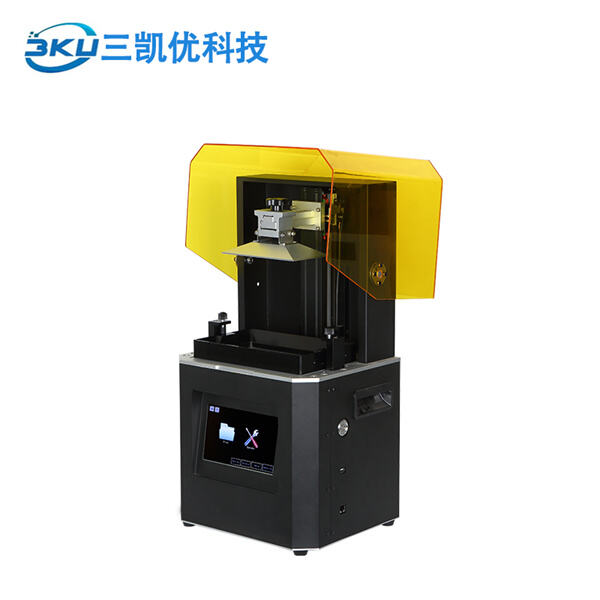

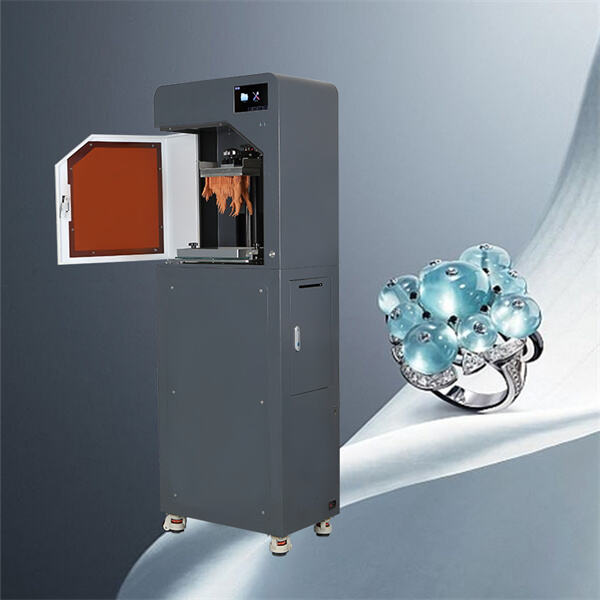

Since 2012 our founder has been working on 3d printing jewelry molds, ranging all the way from FDM to DLP, SLA. He believes in "3d technology that will bring about another industrial revolution"! We try our best to provide more support for technical and service issues for those who are 3D Printer fans and have a strong support for us! We provide considerate support and respond quickly to market demands.

Our printers have been utilized in various industries such as jewelry, 3d printing jewelry molds, Ceramics and more. Our custom services are ideal. We offer a range of custom services, such as the design of the packaging along with the software, the logo, packaging and many more. We offer our customers 3D printers for the cheapest prices, and with the highest quality, functionality and efficacy.

Our printers, based on a unique design, structure, and most importantly our highly skilled team of 3d printing jewelry molds, are used in various industries like Dental Casts and crowns Jewelry casts, Garage Kits, Precise Moldings, and more. We support the provision of free tests. We are able to print stl files on our printers and show you how they function as well as the results before you purchase.

Shenzhen 3KU Technology and Science Co. LTD was established in 2014. Within a few years of marketing and development, our brand 3KU is well-known to 3d printer 3d printing jewelry molds and users. We offer a complete technical support, printing technology, after casting processes, and a lifetime warranty. We provide professional technology and a customized service to help with casting and printing issues across different fields.

Copyright © Shenzhen 3KU Technology and Science Co., LTD. All Rights Reserved Privacy Policy Blog