Once upon a time, there were actual jewelers making beautiful jewelry by hand. They many hours designing beautiful artwork that takes skill and patience. The process itself was laborious and sometimes a single piece could take hours to complete. And now, there is a new method of jewelry that is rather atypical and intriguing to say the least. This method is the 3D printing.

Invention of 4th Dimension (3D Printings): It requires a special type of machine which combines layers of material to make a three dimensional object. This technology has revolutionized the way jewelry is made. This certainly streamlines the process of coming up with special, one-off jewelry creations.

Today, there is special software in which jewelers can draw sketches for their future designs. Once they have completed their design, we can feel than confidence that printing it out through 3D printers is very achievable. This saves a hell lot of time and actually helps them to come up with exclusive designs, which is almost impossible using the hand-making method.

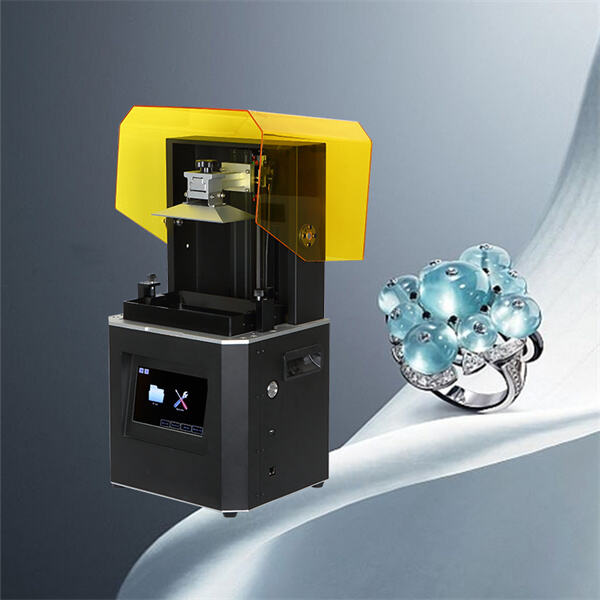

3D PrinterAnother term used for circuit manufacturing process is 3D printing, and these machines which print circuits are called a 3d printer. What the Printer Does This printer takes a digital file of whatever you want to build (essentially, it is able to read blueprint files) and produces physical objects layer by layer finely building upon itself in material. WAX AND RESIN: Wax and resin are the most commonly used materials to make jewelry using 3D printing.

To form the mold, usually wax is used. A mold is just the shape a jewelry will make in metal sense. The jewelry is made with the help of a wax mold. Resin is used to create the end product, on the other hand. The mold is filled with resin, then recipe needs to be thrown out on the stretch and it becomes redone into something shiny and beautiful.

One of the biggest reasons jewelers take to 3D-printing is that this technology helps them produce intricate and complicated designs. These are designs that would be near impossible for a human to assemble. Creating designs with computer software that can be printed out by a 3D printer is also an option for jewelers.

Creating Custom Jewelry with 3D Printing Technology As a result, all of our pieces have the potential to be an individual and unique piece for you. For customers ready to commit for life : Jewelers can craft a piece from scratch with their customer, making them an earring or ring that expresses exactly what they want it to. Once this design is finalized, the jeweler can print it using a 3D printer.

Based on unique design and structure, especially our outstanding research team, our printers are utilized in a variety of sectors, like 3d printing for jewelry casting, Jewelry cast, Garage Kit, Precise Molding, ect. We encourage the supply of free examples. We can print stl documents on our printers and show you how they operate and the results before you purchase.

3d printing for jewelry casting is established in the year 2014. Within just a few years of developing and marketing, our brand 3KU is known well by 3d printer lovers and users. We offer a wide range of technical support that includes printing technology, post-processing, casting techniques, and a lifetime warranties. We provide highly skilled support and technology. We we can resolve printing and casting issues in various areas.

Our founder is working on 3d printers since 2012, from FDM, DLP, SLA. He believes that "3d printing for jewelry casting is going to be the catalyst for a new revolution in the industrial sector". We do our best to provide greater technical and service support for those who are 3D Printer fans and have a strong support for us! We provide a friendly service, and react quickly to the market.

Our printers have been utilized in many industries including jewelry, Temples Dentals, Ceramics etc. We offer a wide range of customized services. The customize services include the 3d printing for jewelry casting, the customized logo, the software design, more function and the personalized packaging. We provide our clients the best 3D printers for their money that are of good quality, practical utility and high-efficiency.

Copyright © Shenzhen 3KU Technology and Science Co., LTD. All Rights Reserved Privacy Policy Blog