Une créatrice de bijoux qui souhaite que ses conceptions soient plus attrayantes et intéressantes ? Dans ce cas, une imprimante 3D en résine est probablement faite pour vous ! Il existe de nombreuses imprimantes 3D au choix, et il peut être difficile de décider laquelle est la meilleure pour vous. Cependant, lisez la suite et nous vous expliquerons comment une imprimante 3D en résine peut améliorer votre processus de création de bijoux pour obtenir les meilleures conceptions.

Les gens fabriquaient autrefois des bijoux en les sculptant ou en les coulant dans des moules. Cela pouvait être un processus long — parfois des jours, voire des semaines. Maintenant, grâce aux nouvelles technologies, nous pouvons créer certains bijoux de manière plus efficace. L'imprimante 3D à résine vous permet de travailler beaucoup plus rapidement qu'avec les méthodes traditionnelles. Cette imprimante vous permettra de réaliser un design de bijou et de l'imprimer en quelques heures seulement ! Cela signifie que vous n'avez pas besoin de fabriquer des bijoux à la main et pouvez ainsi passer votre temps à réfléchir à de nouvelles idées. Vous pouvez même imprimer de nombreuses pièces en une seule fois, ce qui accélère tout et augmente votre productivité !

Les imprimantes 3D à résine sont idéales pour créer des pièces de bijouterie uniques et détaillées qui attirent l'attention. L'un des avantages de ce type d'imprimante est que vous pouvez contrôler précisément l'épaisseur de vos pièces et leur apparence. Cela signifie que vos conceptions ressembleront exactement à ce que vous espériez, ce qui est extrêmement puissant. Vous pouvez également générer des idées et être sûr qu'elles seront réalisables, ce qui vous permet de repousser les limites de la créativité.

Pour un créateur de bijoux, rester à jour avec les nouveaux styles et tendances que les gens recherchent peut être un défi. Les clients recherchent souvent de nouveaux designs, ce qui en fait une tâche difficile pour répondre à leurs attentes. Avec une imprimante 3D à résine, vous pouvez mettre en file d'attente de nombreux designs rapidement et efficacement ! L'imprimante offre bien plus : vous pouvez créer des bijoux tendance/modernes (ceux-là attirent certainement l'œil) ou même rester sur des pièces classiques, que tout le monde adore. C'est parce que, en étant flexible, vous pouvez rester au courant des désirs des gens et essayer de nouvelles méthodologies — avec peu de contraintes.

La meilleure partie de la création de bijoux est qu'elle vous permet de prendre une idée et de la transformer en un objet physique qui peut être vu, touché. Les sorciers de l'impression 3D en résine transforment les conceptions que vous avez en tête en objets tangibles. Vous pouvez examiner ces créations sous un angle différent directement dans vos mains. Cela peut vous aider à ajuster et affiner encore plus vos conceptions. Il y a simplement une grande satisfaction à avoir créé quelque chose que nous aimons et que les clients apprécieront vraiment.

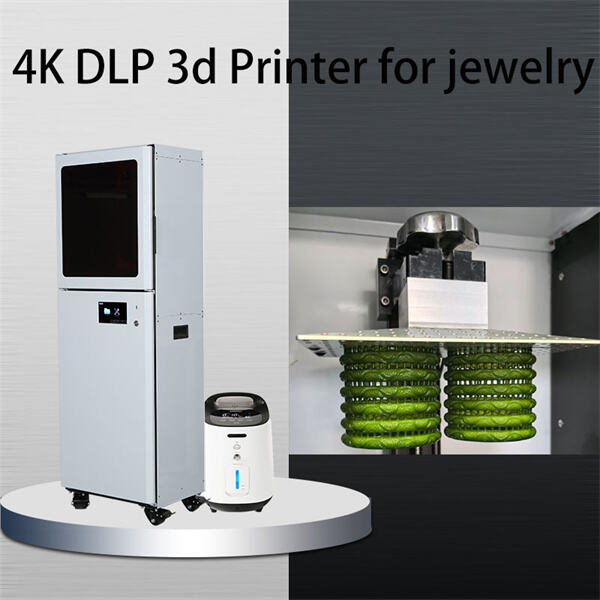

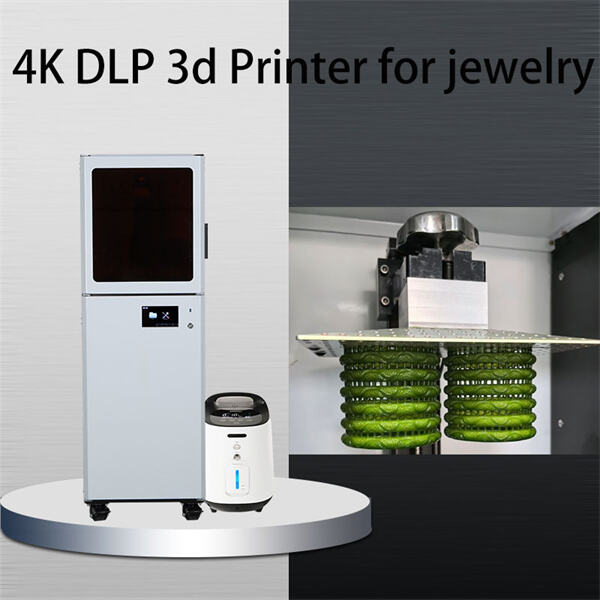

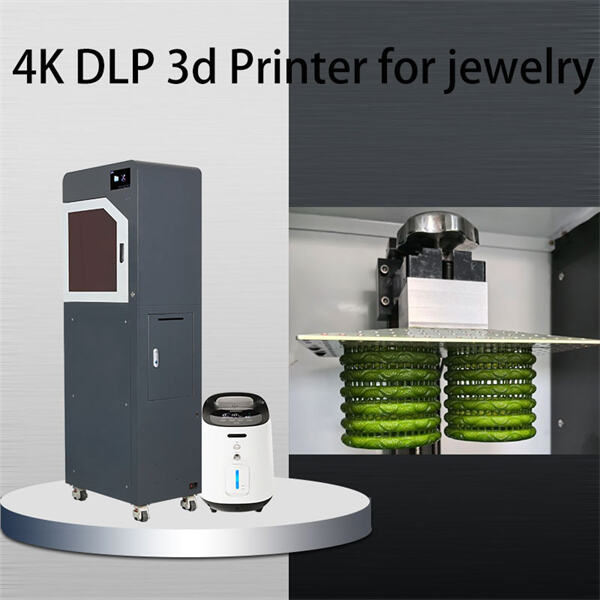

Shenzhen 3KU Technology and Science Co. LTD a été fondée en 2014. En quelques mois seulement, 3KU est devenue une marque incontournable pour les utilisateurs et les passionnés d’imprimantes 3D. Nous proposons une gamme complète d’assistance technique, comprenant des imprimantes 3D résine pour la bijouterie, des solutions de post-traitement, des techniques de fonderie ainsi qu’une garantie à vie. Nous offrons des services technologiques professionnels et sur mesure afin de résoudre les problèmes d’impression et de fonderie dans divers domaines.

Imprimante 3D résine pour la bijouterie : le fondateur de notre entreprise travaille sur les imprimantes 3D depuis 2012, en commençant par les technologies FDM, DLP et SLA. Il est convaincu que « la technologie 3D déclenchera une nouvelle révolution industrielle » ! Nous faisons tout notre possible pour offrir un meilleur service et une assistance technique de qualité aux amateurs d’imprimantes 3D, que nous soutenons avec constance et détermination ! Nous proposons l’emballage en tour la plus compétitive du marché. Nous assurons un service convivial et sommes capables de réagir rapidement aux évolutions du marché.

Imprimante 3D à résine pour la bijouterie, dotée d'une disposition et d'un design originaux, notamment grâce à notre excellente équipe de recherche ; nos imprimantes sont utilisées dans une variété de secteurs, tels que la fonderie dentaire (couronnes et bridges), la fonderie de bijoux, les kits de garage, le moulage précis, etc. Nous offrons des échantillons gratuits. Nous pouvons imprimer des fichiers STL sur nos imprimantes et vous montrer leur fonctionnement ainsi que les résultats obtenus avant votre achat.

Nos imprimantes sont utilisées dans de nombreux secteurs, notamment la bijouterie, la dentisterie temporaire, la céramique, etc. Nous proposons une vaste gamme de services personnalisés. Ces services incluent l’imprimante 3D à résine pour la bijouterie, la personnalisation du logo, la conception de logiciels, l’ajout de fonctionnalités supplémentaires et un conditionnement personnalisé. Nous fournissons à nos clients les meilleures imprimantes 3D pour leur argent, réputées pour leur qualité, leur utilité pratique et leur haute efficacité.

Droits d'auteur © Shenzhen 3KU Technology and Science Co., LTD. Tous droits réservés Politique de confidentialité Blog