Par exemple, le design de l'imprimante 3D LCD DLP permet aux utilisateurs de produire des pièces avec des détails extrêmement fins. Cela est utile dans ces cas où NOUS souhaitons vraiment que nos objets soient un peu spéciaux. L'imprimante y parvient grâce à un type spécial de lumière qui solidifie la résine liquide. Chaque couche implique de projeter de la lumière UV à travers la résine, la durcissant progressivement jusqu'à ce qu'un objet entier soit terminé. Cela signifie que nous pouvons fabriquer chaque petite partie de l'objet avec des dimensions très précises.

Ce que j'aime avec l'imprimante 3D LCD DLP, c'est qu'elle imprime si vite. Certaines imprimantes 3D doivent déposer un tout petit point à la fois ; cette imprimante traite des couches entières en octobre, Spiffing. Ainsi, elle accélère tout le processus d'impression, rendant votre flux de travail plus rapide et efficace, sinon vous êtes souvent pressés, donc cela devient avantageux.

Francis Bitonti (ci-dessus) est un artiste qui utilise des imprimantes 3D de style LCD DLP pour créer des designs incroyables et ornés. L'une de ses pièces les plus célèbres est une robe entièrement imprimée en 3D ! Elle montre vraiment à quel point on peut être créatif avec cette technologie et elle a inspiré beaucoup de gens pour de nouveaux projets.

Alors, comment ça fonctionne – une imprimante 3D LCD DLP ? Cela commence par un programme informatique qui peut être utilisé pour créer un design 3D. C'est un plan pour l'objet que vous allez créer. Une fois que le design d'impression est terminé et préparé pour l'impression, nous allons imprimer ce design en 3D.

L'imprimante durcit ensuite la résine liquide à l'aide de cette lumière spéciale dont nous avons parlé plus tôt et puis, PAN ! Elle effectue alors soigneusement cette opération couche par couche délicate jusqu'à ce que l'objet entier soit terminé. Après l'impression, il sera retiré de l'imprimante et lavé pour enlever toute trace de résine restante. De cette manière, vous pouvez vous assurer qu'il aura bonne apparence à la fin.

Donc, l'imprimante 3D LCD DLP fait tout cela de nombreuses façons nouvelles et passionnantes. Probablement le plus grand changement est qu'elle simplifie la création d'objets par les gens. Vous pouvez imprimer presque n'importe quoi qui vous passe par la tête, allant des bagues délicates aux grandes sculptures en passant par les maquettes architecturales. C'est ce qui donne beaucoup d'espace pour être créatif et s'exprimer.

Non seulement cela, mais l'imprimante permet d'imprimer avec encore plus de détails microscopiques que ce qui était auparavant possible. Autrement dit, elle permet de produire certains objets qui étaient très difficiles ou carrément impossibles à fabriquer avec les méthodes traditionnelles. Pour les artistes, les concepteurs et les inventeurs, cela ouvre un tout nouveau monde de possibilités.

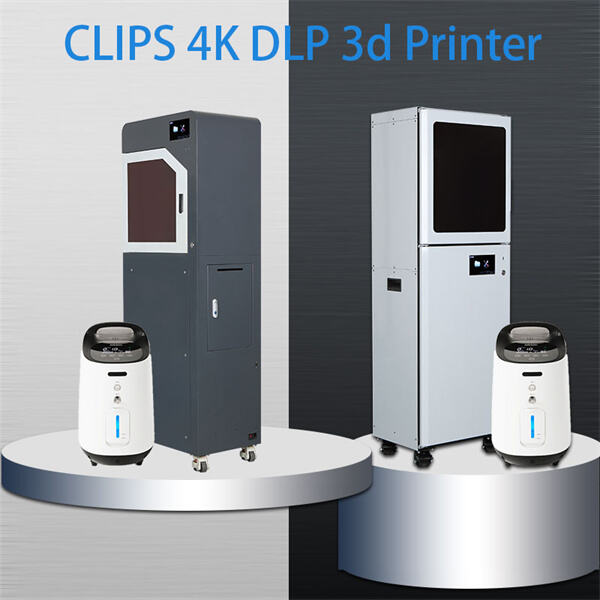

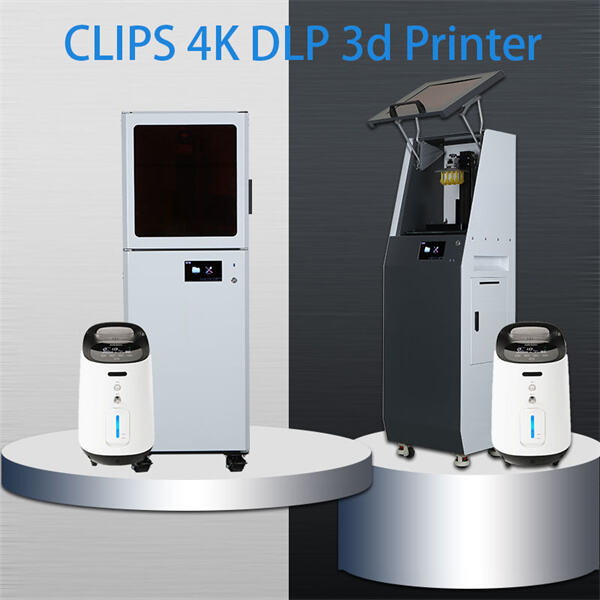

Le fondateur de notre entreprise travaille sur les imprimantes 3D depuis 2012, en commençant par les imprimantes 3D LCD DLP et SLA. Il est convaincu que « la technologie 3D créera une nouvelle révolution dans le secteur industriel ». Nous faisons de notre mieux pour offrir un meilleur service et un soutien technique aux passionnés d’imprimantes 3D, que nous soutenons avec constance et détermination ! Nous proposons l’emballage en tour le plus compétitif du marché. Nous sommes en mesure d’offrir un service attentionné et de répondre rapidement aux besoins du marché.

Fondé sur un design et une structure uniques, en particulier pour notre imprimante 3D LCD DLP, nos imprimantes sont utilisées dans divers secteurs industriels, y compris la fonderie dentaire et les couronnes, la fonderie de bijoux, les kits de garage, le moulage précis, etc. Les échantillons sont gratuits. Nous pouvons imprimer des fichiers STL sur nos imprimantes et vous montrer comment elles fonctionnent ainsi que les résultats avant votre achat.

Shenzhen 3KU Technology and Science Co. LTD a été fondée autour de l’imprimante 3D LCD DLP. En seulement quelques mois, 3KU est devenue une marque reconnue auprès des propriétaires d’imprimantes 3D et de leurs adeptes. Nous fournissons une assistance technique complète, couvrant notamment les technologies d’impression, les techniques de coulée en post-traitement, ainsi qu’une garantie à vie. Nous sommes en mesure d’offrir une expertise technologique hautement professionnelle ainsi que des services sur mesure afin de résoudre les problèmes liés à la coulée et à l’impression dans divers domaines.

Nos imprimantes sont utilisées dans divers secteurs, notamment la bijouterie, les temples, l’odontologie, la céramique, etc. Nous proposons des services entièrement personnalisés. Nous fournissons une imprimante 3D LCD DLP sur mesure. Ces services comprennent la conception de l’emballage ainsi que du logiciel, du logo, de l’emballage et de nombreuses autres fonctionnalités. Nous offrons à nos clients les imprimantes 3D les moins chères, tout en garantissant une haute qualité, une grande praticité et une efficacité optimale.

Droits d'auteur © Shenzhen 3KU Technology and Science Co., LTD. Tous droits réservés Politique de confidentialité Blog