Si vous utilisez l'impression 3D assez souvent, il se peut que vous ayez déjà rencontré les technologies DLP et SLA. Cependant, que signifient réellement toutes ces abréviations ? Mais laquelle est meilleure pour vos projets ? Cet article examinera les différences entre l'impression DLP et SLA. Leurs forces et faiblesses sont analysées séparément — donc, sur la base de ces analyses, nous recommandons à quoi chaque modèle est le mieux adapté.

Le DLP et le SLA sont deux types différents de techniques d'impression 3D utilisant le traitement par lumière, qui transforment la résine liquide en un modèle solide. Tout ce travail est réalisé couche par couche, ce que j'ai trouvé très fascinant ! DLP — Digital Light Processing, SLA — Stereolithography. La différence entre ces méthodes réside dans leur utilisation de la lumière pour polymériser ou durcir la résine.

L'impression DLP, quant à elle, utilise un projecteur numérique pour projeter de la lumière sur toute une couche en une seule fois. De cette manière, toute la couche peut se solidifier simultanément. C'EST CE QUI REND L'IMPRESSION DLP BEAUCOUP PLUS RAPIDE QUE L'SLA. En revanche, l'SLA passe un laser sur l'extérieur de chaque couche pour en dessiner le contour. Cette méthode spécifique permet à l'SLA de produire des formes très détaillées et complexes. D'autre part, le DLP peut être légèrement moins précis que l'SLA. C'est parce que la lumière peut être légèrement déviée en passant à travers la résine, ce qui pourrait affecter sa forme finale.

Comme nous l'avons dit précédemment, l'impression DLP est en général plus rapide que celle par SLA. Si vous devez produire un grand nombre de pièces très rapidement, cette vitesse peut être un avantage majeur. Supposons que vous réalisez un projet de petites pièces et que cela prend trop de temps, le DLP pourrait également être utile. Le SLA est généralement meilleur pour créer des formes avec des détails très fins. Les pièces plus sophistiquées : le laser utilisé dans l'impression SLA permet des formes bien plus précises et complexes — ce qui en fait le choix idéal pour les objets nécessitant des dimensions exactes.

Une différence moins fondamentale entre les processus DLP et SLA concerne les types de résine utilisés par chacun. Étant donné que l'impression SLA peut travailler avec une gamme plus diversifiée de résines, offrant des résines flexibles et des résines d'ingénierie à haute résistance pouvant résister à la chaleur et à la pression. Cette gamme de matériaux est ce qui rend le SLA un choix idéal pour des pièces robustes. Par exemple, pour des assemblages qui doivent supporter beaucoup de contrainte, dans ce cas, le SLA est un bon choix.

En revanche, l'impression DLP dispose généralement d'une sélection plus limitée de résines conçues pour la commodité et des temps de guérison rapides. Bien qu'elles ne soient pas aussi solides ou résistantes à la chaleur que certaines résines SLA, pour de nombreuses applications qui n'exigent pas une durabilité exceptionnelle et des capacités à haute température, elles fonctionnent assez bien. Si vous travaillez sur des objets décoratifs ou des modèles, par exemple, les résines DLP pourraient être un meilleur choix.

Généralement, l'impression DLP est une meilleure option pour vous si : vous cherchez à fabriquer rapidement de nombreuses pièces et qu'il n'y a pas besoin de pièces solides ou très détaillées. Mais si vous fabriquez des pièces nécessitant précision ou exactitude, l'impression SLA sera mieux adaptée à votre application et offrira un plus large choix de matériaux.

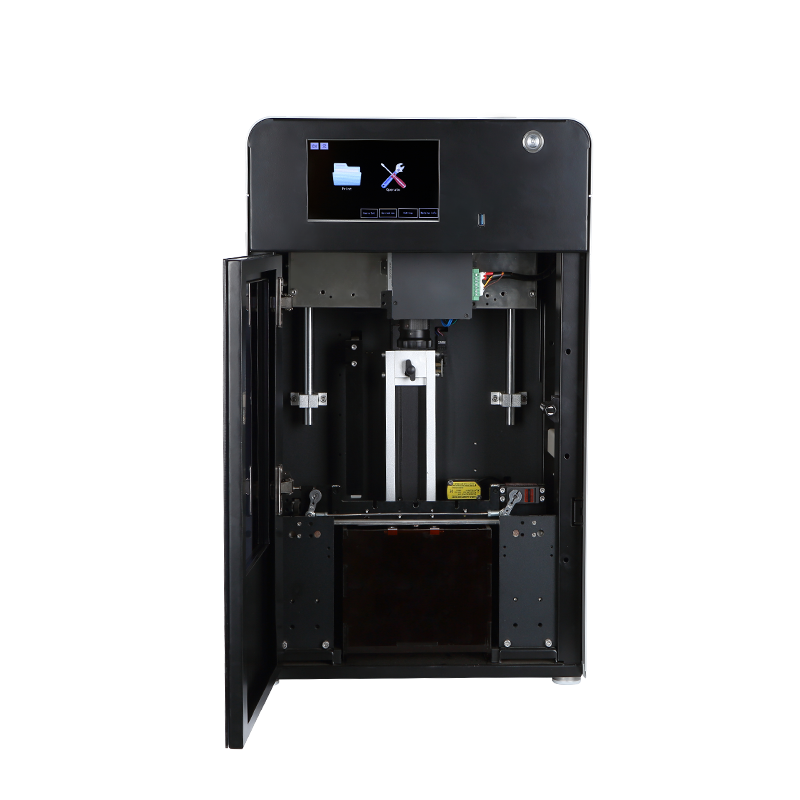

Nos imprimantes ont été utilisées dans divers secteurs industriels DLP et SLA, tels que la bijouterie, les prothèses dentaires, la céramique, etc. Nous proposons des services sur mesure parfaitement adaptés à vos besoins. Ces services personnalisés comprennent la conception de l’apparence extérieure, le logo personnalisé, la conception logicielle, des fonctionnalités supplémentaires ainsi que l’emballage personnalisé. Nous fournissons à nos clients des imprimantes 3D aux prix les plus abordables, tout en garantissant une haute qualité, une grande utilité et une excellente efficacité.

DLP et SLA a été fondée en 2014. En seulement quelques années de développement et de commercialisation, notre marque 3KU est devenue très populaire auprès des passionnés et des utilisateurs d’imprimantes 3D. Nous offrons un large éventail de supports techniques, notamment en matière de technologie d’impression, de post-traitement, de techniques de fonderie, ainsi qu’une garantie à vie. Nous mettons à disposition un soutien technique hautement qualifié. Nous sommes en mesure de résoudre les problèmes liés à l’impression et à la fonderie dans divers domaines.

Les fondateurs de notre entreprise spécialisés dans les technologies DLP et SLA travaillent sur les imprimantes 3D depuis 2012, en commençant par les technologies FDM, DLP et SLA. Ils sont convaincus que « la technologie 3D déclenchera une nouvelle révolution industrielle » ! Nous faisons tout notre possible pour offrir un service et une assistance technique de qualité supérieure aux passionnés d’impression 3D, que nous soutenons avec constance et détermination ! Nous proposons l’emballage en tour le plus compétitif du marché. Notre service est convivial et nous sommes capables de réagir rapidement aux évolutions du marché.

Nos imprimantes, conçues selon une architecture originale (DLP et SLA), ainsi que, surtout, notre remarquable équipe de chercheurs, sont utilisées dans de nombreux secteurs tels que la fabrication de prothèses dentaires et de couronnes, la fonderie de bijoux, les kits de modélisme automobile, les moulages de précision, et bien d’autres encore. Nous offrons des échantillons gratuits : vous pouvez nous envoyer vos fichiers STL, et nous les imprimerons à l’aide de nos imprimantes afin de vous montrer leur fonctionnement et les résultats obtenus avant tout achat.

Droits d'auteur © Shenzhen 3KU Technology and Science Co., LTD. Tous droits réservés Politique de confidentialité Blog