C'est un matériau unique fabriqué en cuisanant de l'argile à des températures élevées. La céramique peut être une argile, et lorsque l'argile est chauffée, elle se transforme en un lien solide qui devient très résistant ; ce qui rend la céramique importante. La céramique est utilisée depuis des siècles, voire bien plus d'un millénaire ! On sait qu'elle a été utilisée pour créer une grande variété d'objets, y compris des assiettes, des tasses et des bols, ainsi que des bijoux ou même des statues. Heureusement, avec les nouvelles technologies comme l'impression 3D, nous pouvons désormais créer des choses incroyables en céramique qui étaient auparavant impossibles à réaliser !

Donc, la prochaine question est, comment faisons-nous pour créer une céramique imprimée en 3D ? La première étape consiste à imiter ce que l'on veut construire dans l'ordinateur. Cela implique une carte en feuille et est réalisé en utilisant un logiciel spécifique qui nous aidera à générer un modèle virtuel de l'artefact. Bien que concevoir soit excellent, cela peut également être très chronophage et nécessiter certains compétences pour obtenir un résultat parfait. Nous utilisons un processus où nous créons notre conception, puis l'envoyons pour être imprimée dans une imprimante 3D spéciale qui travaille avec des matériaux céramiques.

Donc, pour commencer, l'imprimante déposera une très fine couche de poudre céramique. Ensuite, elle ajoute un type unique de Velcro à chaque niveau. Chaque objet est construit à partir de ces couches combinées et le processus se répète automatiquement jusqu'à ce qu'un objet entier soit renouvelé. Lorsque l'objet est terminé, il est ensuite placé dans un four pour être cuit et durci - beaucoup comme les céramiques traditionnelles.

Cette céramique imprimée en 3D a de nombreux usages. Un bel exemple étant des sculptures magnifiques que les gens peuvent admirer. Elles peuvent également être utilisées pour créer des objets du quotidien que nous utilisons réellement, comme des tasses et des bols, etc. De plus, la solidité et la durabilité des composants céramiques produits par l'impression 3D peuvent également être cruciales dans des applications de pointe telles que l'aérospatial ou le médical.

Dans ce billet, nous vous présentons les types de choses désormais possibles grâce à l'impression 3D de céramiques. Les médecins peuvent utiliser des os en céramique imprimés en 3D, et les personnes ayant cassé un os pourront guérir plus rapidement. Non seulement ces os en céramique sont solides et légers, mais ils peuvent également être façonnés sur mesure pour chaque patient. Cela signifie que chaque personne reçoit un os conçu spécialement pour elle !

Que ce soit par des méthodes traditionnelles ou par impression 3D, les céramiques possèdent distinctement les propriétés uniques suivantes. La propriété principale est qu'elles sont beaucoup plus dures et résistantes. Cette caractéristique est recherchée pour la fabrication d'objets tels que des assiettes ou des tasses, deux artefacts qui sont lavés à répétition et que nous ne voulons pas voir se casser de sitôt.

Pour conclure, la 3ème vague dans la technologie de l'art traditionnel du point de vue de la céramique. (priez pour que d'une manière ou d'une autre nous serons assez ouverts pour l'adopter bientôt) L'impression 3D a permis un tout nouveau niveau de détail et de complexité, qui serait fastidieux voire impossible à réaliser manuellement par les artistes pour créer des formes et des motifs. La possibilité d'expérimenter avec différentes techniques et matériaux est un élément important pour les artistes en céramique, tout comme cela se révèle bénéfique lorsqu'appliqué par un fabricant de meubles utilisant certaines technologies 3D, ce qui leur permet de dépasser les applications traditionnelles.

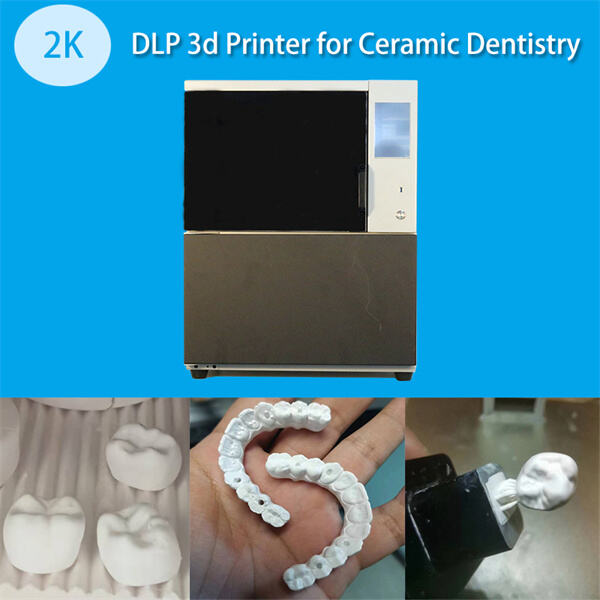

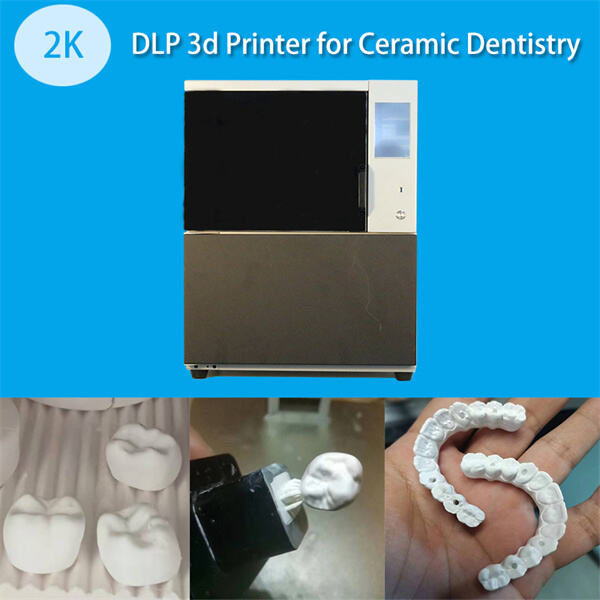

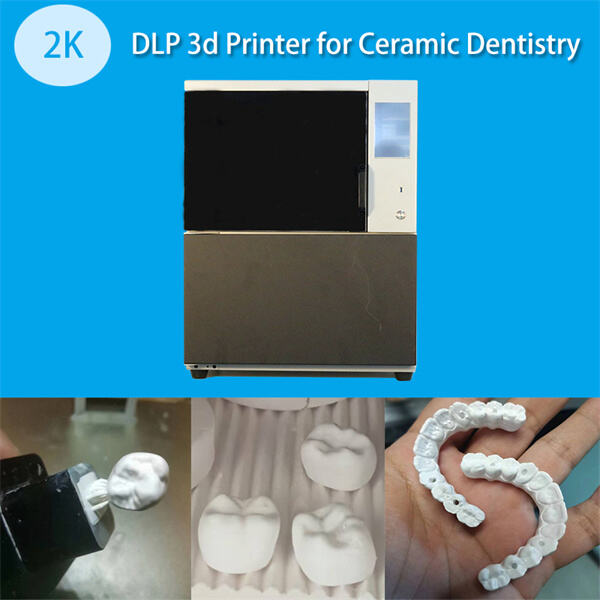

Nos imprimantes, basées sur une conception et une structure uniques, et surtout sur notre équipe hautement qualifiée spécialisée dans l’impression 3D de matériaux céramiques, sont utilisées dans divers secteurs tels que la fabrication de modèles dentaires et de couronnes, la fonderie de bijoux, les kits de maquettes, les moulages de précision, et bien d’autres encore. Nous proposons des essais gratuits. Nous sommes en mesure d’imprimer des fichiers STL sur nos imprimantes et de vous montrer leur fonctionnement ainsi que les résultats obtenus, avant tout achat.

Nos imprimantes ont été utilisées dans divers secteurs, notamment la joaillerie, l’impression 3D de matériaux céramiques, la céramique, et bien d’autres encore. Nos services sur mesure sont idéaux. Nous proposons une gamme de prestations personnalisées, telles que la conception de l’emballage ainsi que du logiciel, du logo, de l’emballage, et bien plus encore. Nous offrons à nos clients des imprimantes 3D aux prix les plus compétitifs, alliés à une qualité, une fonctionnalité et une efficacité optimales.

Notre fondateur travaille sur les imprimantes 3D depuis 2012, avec des technologies FDM, DLP et SLA. Il est convaincu que « l’impression 3D de matériaux céramiques sera le catalyseur d’une nouvelle révolution dans le secteur industriel ». Nous faisons tout notre possible pour offrir un soutien technique et service accru aux passionnés d’imprimantes 3D, qui nous accordent également un soutien indéfectible ! Nous proposons un service convivial et réactif face aux évolutions du marché.

Shenzhen 3KU Technology and Science Co. LTD a été fondée en 2014. En seulement quelques années de promotion et de développement de notre marque, 3KU est devenue bien connue des passionnés et utilisateurs d’imprimantes 3D. Nous proposons une large gamme d’assistance technique, couvrant notamment les technologies d’impression, la post-production, les matériaux céramiques pour impression 3D, ainsi qu’une garantie à vie. Nous offrons un service et une technologie hautement professionnels. Nous sommes capables de résoudre les problèmes liés à l’impression et au moulage dans divers domaines.

Droits d'auteur © Shenzhen 3KU Technology and Science Co., LTD. Tous droits réservés Politique de confidentialité Blog