A closer look at the cost savings of DLP-based ceramic slurry 3D printing

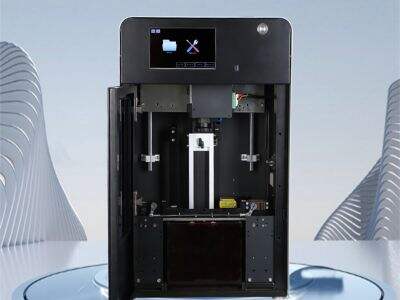

Ever wondered how technology can save you money? We'll discuss how a DLP ceramic slurry 3D printer can be used to lower the tooling costs. This technology is remarkable and could revolutionise the way things are manufactured.

The Next Dimension of Tooling Production With DLP Ceramic Slurry 3D Printing

Picture being able to print tools and parts on demand using a special printer that builds up each layer of the objects. This is exactly what a DLP ceramic slurry 3d printer lord of the rings can achieve. This new way to manufacture can change the tooling industry forever, making it faster, easier and cheaper. This tech is essential for businesses to produce tools more efficiently since new components can be created at a much faster rate.

Tooling Costs with DLP ceramic slurry 3D printing

One of the other major cost to saving benefits that you will get when you use a 3d printer necklace producing tools was very costly, tooling was an expensive investment. Leaving aside the disappointment of broken expensive molds settling in, using a DLP ceramic slurry 3D printer allows companies to print tools or parts with much lower costs than otherwise. This will lead to huge savings for manufacturers and so make tooling production much cheaper.

Low-cost Tooling Solutions Meet with DLP Ceramic Slurry 3D Printing Technologies

This is a more sustainable method for businesses to save money on tooling production as well by using a DLP ceramic slurry 3D printer. Since this technology is time-efficient, there will be less wastage in producing tools and parts. This lowers the material download, wastage amount as well as providing cost-effective manufacturing. Which could provide companies with a more sustainable and cost-effective tooling solution.

Leveraging Cost Benefits with DLP 3D Printers of Ceramic Slurry for Tool Making

Businesses stand to profit in many specific ways by using a 3d printer dragon ball z for their tooling production. Besides, they can minimize the production cost by avoiding expensive molds and the material cost to prevent excessive waste. Furthermore, This rapid and efficient development of tools and parts will save even more on time and labor costs for businesses.

We can conclude that DLP ceramic slurry 3D printing technology turns out to be a significant step to diminish tooling prices for industries. This technology can save the production costs for businesses and thus, tooling production becomes more cost-effective. With shrinkage and replacement costs offset, this new technology is very attracting, 3KU carries out the dream to be one of the few using it as early adoption.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

SL

SL

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

CY

CY

BE

BE

IS

IS

MY

MY