3D Wax PrintingThe is a very impressive technology, that allows jewelry makers to produce individualized Benzel instead of common ones by giving him some insane design glands like no other. Computer software is used by the jewelry makers, also known as jewelers to design their wonderful pieces. After they finalize their 3-D design, it is turned over to a computer that sends the specification to a specialized printer - in this case an industrial-grade 3D wax printer. The printer then produces a wax mold that takes the same shape as what the designer imagined for his jewelry.

The model can now be cast in metal (as and when the wax version is done, original jewelry can then simply made by traditional means). Casting - pouring molten metal into a mold to cast the final piece This incredible technology enables skilled jewellers to put together designs that in many cases are intricately difficult or even impossible for a pair of hands.

3D wax printing has truly revolutionized the way jewelry is crafted. Prior to this technology, the jewelers would take very long time in designing their designs. This way, their 3D wax model can be produced in a few hours with the help of innovative 3d printing services and not for days like previously. This allows them to work quicker and produce more advanced stages at a higher velocity of output for their customers.

Jewelry designers come to life with their creative in 3D wax printing. They can say something like: At 3AM, they have the ability to make very specific pieces that are impossible by hand. This process brings them new shapes and styles to experiment with, it also gives then the opportunity add fine detail elements they could not achieve otherwise.

This significantly widens the scope of what jewelry designers are capable of. They are able to expand the boundaries of thinking and produce one-off jewellery that is different from all other jewellers. In this way, no two pieces ever have to look the same and can truly be something fresh & new that accurately shows off how the band envisions their art.

3D wax printing has revolutionized the complete process of crafting jewelry. This will enable jewelry designers to reproduce complex and elaborate designs at a much faster rate with even more precision than Tabletop models of the past. In this design process, jewelers could spend days or even weeks to express the same ideas in high quality.

Using 3D wax printing, jewelers are able to create molds of their designs in as little time. They also are able to make updates and even refine it all far quicker than before. It is through this technology that jewelry designers can work more and produce designs of utmost quality in lesser time.

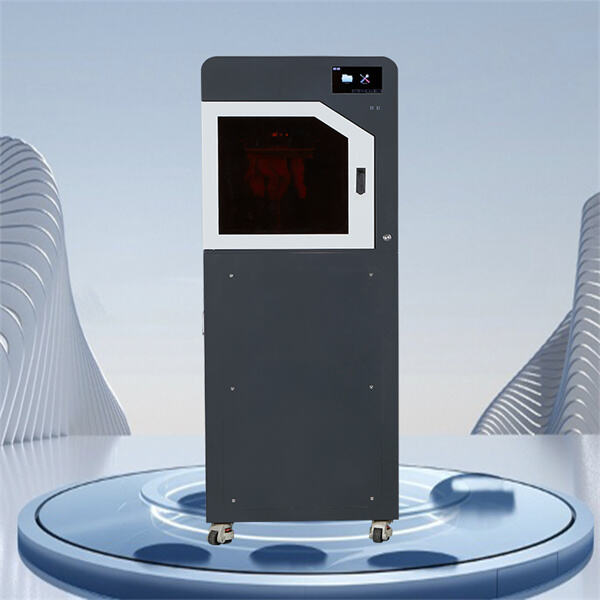

Shenzhen 3KU Technology and Science Co. LTD was founded in 2014. In just a few short months, 3KU has become a household name for 3d printer users and fans. We provide a complete range of technical support that includes 3d wax printing for jewelry, post-processing, casting techniques, and a lifetime warranty. We provide professional technology and customizing services to solve the printing and casting problems in different areas.

Since 2012 our founder has been working with 3D printers from FDM to DLP, 3d wax printing for jewelry. He believes that "3d technology is going to bring about another industrial revolution". We strive to provide more services and technical support for 3D printer lovers who support us in a big way! We have the lowest priced tower packaging. We offer a courteous service and swiftly respond to changes in the market.

Our printers have been used across a 3d wax printing for jewelry of industries, such as Jewelry, Temples Dentals, Ceramics etc.. We offer customized services that are perfect. The services that we customize include the outlook design, the customized logo, the software design, more functionality and the customized packaging. We provide our customers with 3D printers at the most affordable prices with high quality, utility and efficiency.

Based on a unique design and structure, especially our 3d wax printing for jewelry, our printers are used in various industries, including Dental cast and crown, Jewelry cast, Garage Kit, Precise Molding, ect. Samples are free. We can print STL files on our printers, and show you how they operate and the outcomes before you buy.

Copyright © Shenzhen 3KU Technology and Science Co., LTD. All Rights Reserved Privacy Policy Blog