طابعة DLP SLA هي نوع خاص من الطابعات التي تساعد على طباعة أشياء ثلاثية الأبعاد رائعة. تعمل عن طريق استخدام الراتينج، وهو مادة سائلة. هذا الراتينج يتصلب عند تعرضه للضوء ويتحول إلى الشكل المطلوب. الشيء الأكثر إثارة حول هذه الطابعة ثلاثية الأبعاد هو أنها قادرة على إنشاء تصاميم معقدة وتفصيلية للغاية لا يمكن تحقيقها بأنواع أخرى. بمعنى آخر، ما يميز طابعات DLP SLA هو أنك تستطيع رؤية جميع التفاصيل الدقيقة في ما تنتجه.

واحدة من أكثر الطرق شيوعًا التي يتم بها التعرف على الطباعة باستخدام تقنية DLP SLA هي إنتاجها لأجسام ثلاثية الأبعاد معقدة ومتقنة للغاية. آلية عملها رائعة جدًا. الطابعة تشبه مشغل عرض DLP بقوة عالية، حيث ينير الضوء سطح حوض مليء برزين سائل، ويكون على بعد ميكرونيات فقط فوق مكان طباعة الكائن الخاص بك. يستخدم هذا الضوء لتصلب الرزين في مواقع دقيقة جدًا. بهذه الطريقة، تستطيع الطابعة إنشاء أشكال مذهلة طبقة تلو الأخرى. بمجرد انتهاء الطباعة، يجب غسل الكائن وتلميعه لإعطائه مظهر لامع حقيقي.

كيف تعمل طابعات DLP SLA تبدأ العملية بتصميم لجسم على جهاز الكمبيوتر الخاص بك والذي تريد طباعته باستخدام طابعة SLA المستندة إلى DLP. بعد ذلك، ينتقل التصميم للطباعة. تستخدم الطابعة برنامجًا مخصصًا لتقسيم التصميم إلى طبقات رقيقة، نوعًا ما مثل قطع الكيك. ثم تقوم بطباعة كل طبقة واحدة تلو الأخرى. من طبقة إلى أخرى، تتحرك الطابعة للأعلى قليلاً وتضع فيلمًا آخر من المسحوق الذي يُبنى فوق السابق. يستمر هذا العملية الطبقيّة حتى يتم تصنيع الجسم بالكامل!

الآن، إذا كنت تخطط للانغماس في تقنية الطباعة DLP SLA، فهناك دليل ينتظر اهتمامك. أولاً، يجب أن تكون متأكدًا من وضع الطابعة في بيئة نظيفة وجافة تمامًا. هذا أمر حاسم، حيث أن الحفاظ على نظافة الطابعة سيساعد ليس فقط في تقليل حالات تسرب الغبار أو الجزيئات الصغيرة عبر مرشح الراتينج مما قد يتسبب بأضرار كبيرة على الأسطح المسطحة الجميلة! بل يمكن أن يؤدي أيضًا إلى طبعات غير مرتبة.

بالإضافة إلى ذلك، كما هو الحال مع أي طباعة ثلاثية الأبعاد جيدة، ستحتاج إلى أن يكون لديك طابعتك مُحَلَّلة بشكل صحيح. المعايرة تعني فقط ضبط الطابعة بشكل صحيح. وهذا يعني التأكد من أن مصدر الضوء يكون في المكان المناسب تمامًا، وأن المنصة التي تقع عليها عملية البناء لا تحتاج إلى نظام غذائي خالٍ من الدهون. إذا لم تكن هذه الأمور صحيحة، فقد تفشل طباعاتك والحصول على أجزاء لا تتطابق من الناحية الجمالية.

الآن، من الواضح أن التجربة مع راتنجات أخرى أيضًا فكرة جيدة للبحث عن الراتنج الذي يعمل بشكل أفضل لمشاريعك المحددة. هناك مجموعة واسعة من أنواع مختلفة من الراتنج، وكل منها له خصائصه المميزة. بعض الراتنجات قادرة على التحرك أو التمدد قليلاً، وهذه ستكون عادةً الأكثر مرونة، بينما تبقى الأخرى صلبة وغير مرنة مثل الإيبوكسي. كلما كانت طباعة أكثر تفصيلًا، كلما أردت أن تكون كل طبقة أرق؛ لذلك فإن بعض الراتنجات تكون أفضل لقطع صغيرة تحتوي على الكثير من التفاصيل، بينما تعمل أخرى بشكل أفضل عند طباعة أجسام أكبر لا تحتاج إلى تفاصيل دقيقة.

تكنولوجيا الطباعة DLP SLA تغيّر الطريقة التي يتم بها تصنيع المنتجات. يمكن للشركات صنع نماذج أولية متطابقة تقريبًا مع المنتج النهائي الذي تخطط لبيعه بسبب الدقة العالية في إنشاء الأشياء. هذا سيتيح للمؤسسات اختبار تصاميمها بشكل أكبر قبل الانتقال إلى الإنتاج الكامل. إنه يمكّنهم من رؤية أفكارهم إذا كانت ذات قيمة وما هي التعديلات المطلوبة.

منذ أن طوّر مؤسسنا طابعة DLP/SLA، عمل مع طابعات ثلاثية الأبعاد ابتداءً من تقنية FDM ووصولاً إلى تقنيتي DLP وSLA. ويؤمن بأن «التقنية الثلاثية الأبعاد ستُحدث ثورةً جديدةً في القطاع الصناعي». ونسعى جاهدين لتقديم دعمٍ أكبر للقضايا الفنية وقضايا الخدمة لأولئك الذين يحبون الطابعات ثلاثية الأبعاد، والذين قدّموا لنا دعماً قوياً! ونوفر خدمةً مهذبةً ونستجيب بسرعةٍ لاحتياجات السوق.

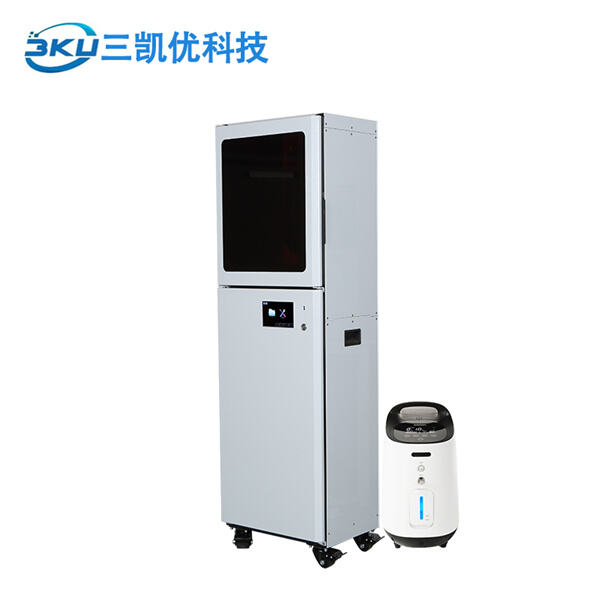

طابعة DLP/SLA ذات تصميمٍ وأسلوبٍ أصليين، وبخاصةٍ بفضل فريق بحثنا المتميز، وتُستخدم طابعاتنا في مجموعةٍ واسعةٍ من القطاعات، مثل صناعة القوالب والتيجان السنية، وصناعة القوالب المجوهراتية، ومجموعات أدوات الورشة (Garage Kit)، والقوالب الدقيقة، إلخ. ونوفر عيّناتٍ مجانية. كما يمكننا طباعة ملفات STL على طابعاتنا وإظهار كيفية عملها والنتائج التي تحققها قبل شرائك لها.

لقد تم استخدام طابعاتنا في مختلف الصناعات مثل صناعة المجوهرات، وطابعات DLP SLA، والخزف وغيرها. وخدمات التخصيص لدينا مثالية. فنحن نقدّم مجموعة واسعة من الخدمات المخصصة، مثل تصميم العبوة جنبًا إلى جنب مع البرمجيات والشعار والعُلب التغليف والعديد غيرها. كما نقدّم لعملائنا طابعات ثلاثية الأبعاد بأقل الأسعار، وأعلى جودةٍ وكفاءةٍ وفعاليةٍ.

تأسست شركة طابعات DLP SLA في عام ٢٠١٤. وبفضل جهود التطوير والتسويق التي بذلناها خلال سنوات قليلة فقط، أصبح اسم علامتنا التجارية «٣KU» معروفًا جيدًا لدى عشاق المستخدمين للطابعات ثلاثية الأبعاد. ونوفر نطاقًا واسعًا من الدعم الفني الذي يشمل تقنيات الطباعة، ومعالجة ما بعد الطباعة، وتقنيات الصب، وضمانًا مدى الحياة. ونقدّم دعمًا فنيًّا عالي المهارة وتكنولوجيا متقدمة. كما يمكننا حل مشكلات الطباعة والصب في مختلف المجالات.

حقوق النسخ © شركة شنتشن 3KU للتكنولوجيا والعلوم المحدودة. جميع الحقوق محفوظة سياسة الخصوصية المدونة