الحلي ذات الجودة ليست شيئًا تُصنع كل يوم، وتحتاج إلى تدريب لتصبح تنافسية في بيئة الإنتاج. إنها عملية مثيرة! هذا هو إذا كنت تريد صنع الحلي من أي نوع كان، يمكن القول إنه الخطوة الأساسية جدًا في تشكيل القوالب. القالب هو بشكل أساسي شكل لتشكيل الحلي التي نرتديها. تعتبر القوالب ضرورية لإنشاء حلي معقدة ومذهلة بصريًا.

حتى الآن، كان الصب سيستغرق كمية كبيرة من العمل والوقت. تم تصميم كل قالب يدويًا، مما قد يستغرق العديد من الساعات أو حتى الأيام لحرفية عالية. ومع ذلك، باستخدام تقنيات أكثر تحديثًا مثل الطابعات ثلاثية الأبعاد، أصبح إنشاء القوالب أقل جهدًا واستهلاكًا للوقت!

يتيح الطابع ثلاثي الأبعاد للمصممين القيام بما يمكنهم بالفعل إنشاؤه للأشكال المجوهرات على القوالب. في أيامنا، عندما كانوا يصممون الطائرات باستخدام قلم رصاص وبرامج خاصة تسمح لهم بإنشاء نماذج ثلاثية الأبعاد لتصاميمهم. بعد ذلك، سيقوم الطابع ثلاثي الأبعاد بتحويل هذه النماذج إلى قوالب فعلية يمكن استخدامها لصب المعادن لإنشاء المجوهرات. إنه سريع وكفؤ، ويساعد المصممين على تحقيق أفكارهم.

ومع ذلك، فإن الطابعة ثلاثية الأبعاد تتيح للمصممين إنتاج القوالب بشكل أسرع وأكثر ملاءمة. الجزء الأفضل هو أنهم يستطيعون إنفاق المزيد من الوقت في ما يحبونه، وهو تصميم المجوهرات بدلاً من صنع القوالب. عندما توفرت هذه التجارب التصميمية نتائجها في أقل من 24 ساعة، كان بإمكان المصممين رؤية أفكارهم تصبح حقيقة بشكل أسرع.

يمكن أن تكون الطباعة ثلاثية الأبعاد أكثر فعالية من حيث التكلفة مقارنة بالطرق المتاحة سابقًا لصنع القوالب. أحد الأسباب هو أن الطابعات ثلاثية الأبعاد تحتاج إلى مواد أقل من الطرق التقليدية. فهي تنتج قوالب بنفس الجودة دون استخدام الموارد بشكل زائد. كما أنها أكثر صداقة للبيئة!

من الخواتم إلى الأساور، الأقراط والسلاسل — يمكن للقوالب المطبوعة ثلاثيًا الأبعاد أن تشكل أنواعًا مختلفة من المجوهرات! هناك مواد أنيقة مختلفة للاختيار منها عند صنع المجوهرات، مثل الذهب والفضة، مما يجعلها أكثر جاذبية للكثيرين الذين يفضلون اللمسات الجميلة والمزج الرائع.

صناعة قوالب المجوهرات باستخدام الطابعات ثلاثية الأبعاد يعتبر تحولًا كبيرًا في عالم المجوهرات. هذه التقنية تصنع قوالب دقيقة ومعقدة للغاية بحيث يكون من المستحيل تقريبًا صنعها يدويًا. ليس فقط توفر هذه التكنولوجيا الوقت والأموال، بل تضمن أيضًا أن القطع النهائية تبدو مثالية كما القوالب.

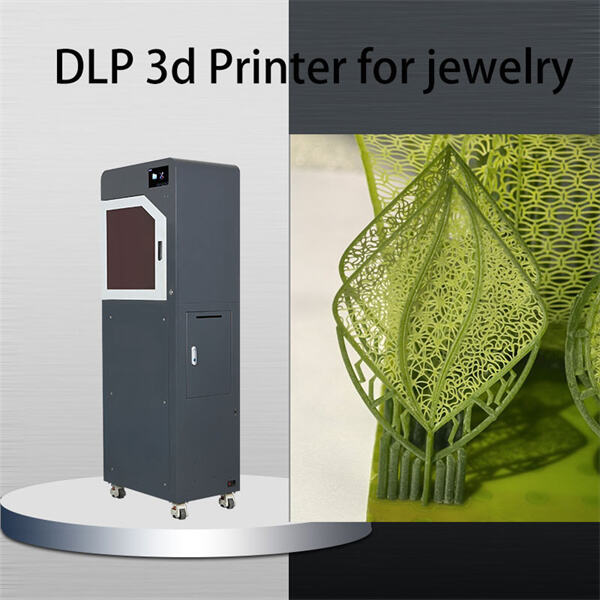

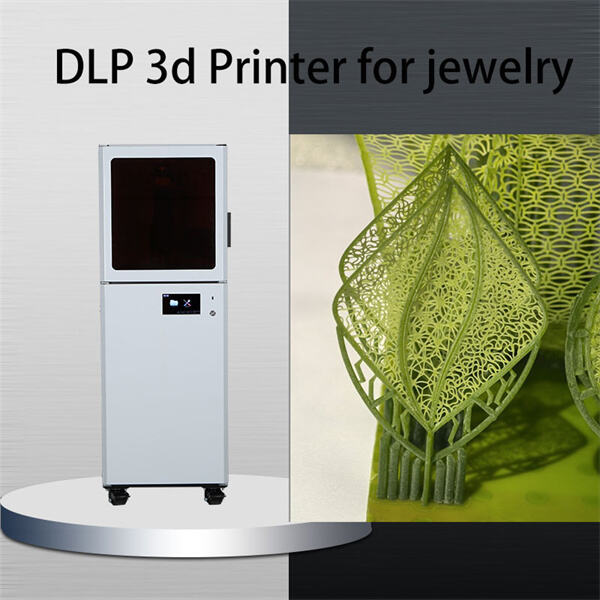

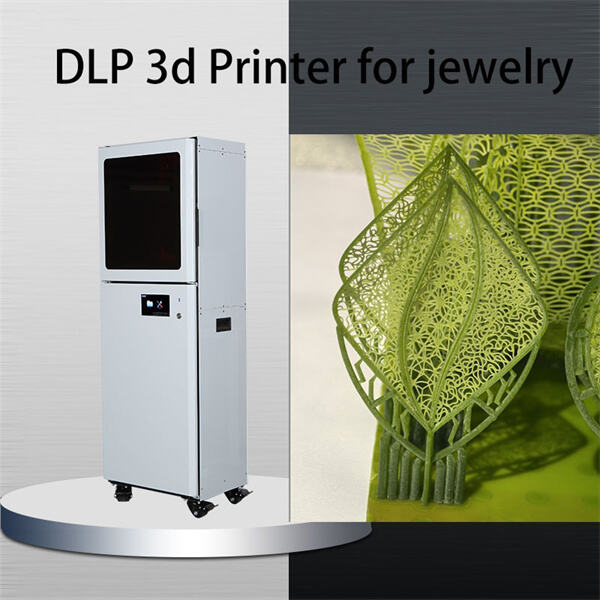

تم إنشاء طابعة ثلاثية الأبعاد لقوالب المجوهرات في عام 2014. وخلال بضعة سنوات فقط من التطوير والتسويق، اكتسبت علامتنا التجارية «3KU» شهرة واسعة بين عشاق المستخدمين للطابعات ثلاثية الأبعاد. ونقدّم مجموعة واسعة من الدعم الفني تشمل تقنيات الطباعة، ومعالجة ما بعد الطباعة، وتقنيات الصب، وضمانًا مدى الحياة. كما نوفّر دعمًا فنيًّا عالي الكفاءة ومتقدمًا تقنيًّا. ويمكننا حل مشكلات الطباعة والصب في مختلف المجالات.

وتُستخدم طابعتنا، التي تستند إلى تصميمٍ فريدٍ وبُنيةٍ مميزةٍ، والأهم من ذلك فريقنا الماهر جدًّا المتخصص في الطابعات ثلاثية الأبعاد لقوالب المجوهرات، في قطاعات صناعية متنوعة مثل القوالب السنية والتيجان، وقوالب المجوهرات، ومجموعات المرآب (Garage Kits)، والقوالب الدقيقة، وغيرها الكثير. وندعم توفير اختبارات مجانية. كما يمكننا طباعة ملفات STL على طابعاتنا وإظهار طريقة عملها والنتائج التي تحقّقها قبل شرائك لها.

تُستخدم طابعاتنا في مجموعة واسعة من الصناعات، مثل الطابعة ثلاثية الأبعاد لقوالب المجوهرات، والمعابد، والأسنان، والسيراميك، وما إلى ذلك. نقدم مجموعة واسعة من الخدمات المخصصة. نوفر نطاقًا واسعًا من الخدمات المخصصة، بما في ذلك تصميم التغليف مع البرمجيات، والعلامات التجارية، والتغليف والعديد من الوظائف الأخرى. نوفر لعملائنا طابعات ثلاثية الأبعاد بأرخص الأسعار مع جودة عالية، ووظيفية وكفاءة.

بدأ مؤسس شركتنا العمل على طابعات ثلاثية الأبعاد منذ عام 2012، بدءًا من تقنيات FDM وDLP وSLA. وهو مقتنعٌ بأن «التقنية الثلاثية الأبعاد ستؤدي إلى ثورة صناعية أخرى». ونسعى جاهدين لتوفير المزيد من الطابعات ثلاثية الأبعاد لقوالب المجوهرات والدعم الفني المُقدَّم لهواة الطابعات ثلاثية الأبعاد الذين يثقون بنا إيمانًا راسخًا! ولدينا تغليف البرج بأفضل الأسعار. كما نقدِّم دعمًا مُراعيًا للاحتياجات، ونستجيب بسرعة لمتطلبات السوق.

حقوق النسخ © شركة شنتشن 3KU للتكنولوجيا والعلوم المحدودة. جميع الحقوق محفوظة سياسة الخصوصية المدونة