هل تريد صنع مجوهراتك الخاصة بفعالية وسرعة؟ إذا كان ذلك هو الحال، فإن الطباعة ثلاثية الأبعاد قد تسمح لك بذلك! يمكنك تصميم وإنشاء قطع مجوهرات رائعة وفريدة من نوعها بإنفاق مبالغ صغيرة على طابعة ثلاثية الأبعاد. الطباعة ثلاثية الأبعاد تغيّر عملية صنع المجوهرات ويمكنك تجربة آلاف الأشكال التي تتحول إلى قطع فنية حقيقية - سنتعلم عن هذا في هذه المقالة.

من الصحيح أن في الأوقات السابقة كان صنع الحلي المخصصة وظيفة مجهدة ومملة. تحديدًا، كان على الحرفيين أن ينحتوا تصميماتهم من الشمع، وقد يستغرق هذا العملية أيامًا أو حتى أسابيع. لم يكن الأمر يستهلك الوقت فقط، بل كان يتطلب مهارة كبيرة أيضًا! لكن اليوم أصبحت هذه قصة قديمة لأن تقنية الطباعة ثلاثية الأبعاد تمكن المصمم من إنشاء نماذج رقمية لتصاميم حليه في غضون ساعات قليلة. بمجرد أن يكون لديهم التصميم، يمكن استخدام الطابعات ثلاثية الأبعاد لطباعة هذه النماذج واستخدام مواد خاصة مثالية لتحويل المنتجات الافتراضية إلى منتجات حقيقية.

يتمتع الطابع ثلاثي الأبعاد بميزة رائعة، مما يسمح لبعض المصممين المحترفين حتى بالتفكير في استخدامه لإنشاء تصاميم ذات مستوى عالٍ جدًا والتي تكون مستحيلة تحقيقها يدويًا. كما أن الطابعة قادرة أيضًا على إنتاج جميع أنواع الأشكال والأنماط المعقدة بسهولة، مما يجعل القطع الصغيرة التي تصنعها تبدو مخصصة تمامًا، وتساعدك على إنشاء حلي ستجذب انتباه المستهلكين حقًا.

يقوم مصممو الحلي بإنشاء نماذج ثلاثية الأبعاد لأحجارهم باستخدام برامج الكمبيوتر. هذا يتيح لك تخيل المنتج النهائي بسهولة قبل إنشائه فعليًا. عندما يكون لدى المصممين نماذجهم، يمكنهم طباعتها باستخدام مواد مختلفة مثل الذهب والفضة أو معادن أخرى تُستخدم بشكل متكرر في صناعة الحلي. وبالتالي، يمكنك توقع الحصول على منتجات ذات جودة عالية ومتينة.

ربما ترغب في إنشاء خاتم خطوبة فريد حقًا لن ينساه الشخص الخاص بك أبدًا، أو ربما يكون الأمر مجرد قطعة من المجوهرات تبدو وتشعر بالراحة على الجسم؛ الطباعة ثلاثية الأبعاد متاحة للغاية وسهلة لأي شخص يريد هذا المنتج. بالإضافة إلى ذلك، بما أن الطابعة يمكنها إنتاج نسخ متطابقة من ملف، فمن السهل إنشاء الأجزاء المرغوبة لعدد كبير من الأشخاص والأحداث المختلفين.

إحدى الفوائد العظيمة لاستخدام طابعة ثلاثية الأبعاد في تصنيع المجوهرات هي مدى سرعتها ودقتها. يستغرق صنع قطعة واحدة من المجوهرات التقليدية غالبًا أيامًا وأحيانًا أسابيع. ومع ذلك، يمكن إكمال قطعة من المجوهرات قد تستغرق من 3 إلى 6 أشهر في غضون ساعات قليلة بمساعدة آلة الطباعة ثلاثية الأبعاد! ولهذه السرعة قيمة لا تقدر بثمن بالنسبة لصانعي المجوهرات المهتمين بإنتاج كمية كبيرة من القطع المخصصة.

هذا هو أحد الطرق التي ساعدت بها الطباعة ثلاثية الأبعاد في تبسيط الأمور - يمكن لمصنعي المجوهرات الآن إنتاج قطع متعددة من تصاميمهم بجهد إضافي ضئيل. هذا يمكّنهم من البقاء على اطلاع باحتياجات الناس وبالتالي تسليم المنتجات في الوقت المحدد بكفاءة، مما سيتيح لهم التركيز بشكل أكبر على الإبداع بدلاً من إضاعة الكثير من الوقت في الإنتاج.

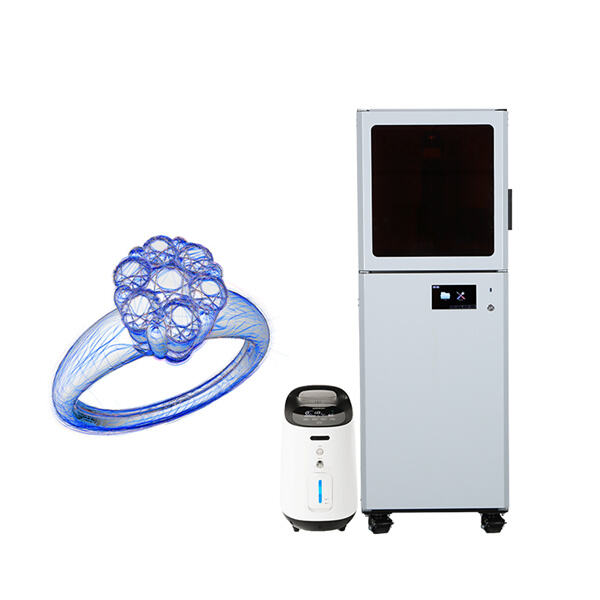

تأسست شركة شينتشن 3KU للتكنولوجيا والعلوم المحدودة في عام 2014. وفي غضون بضعة أشهر قصيرة فقط، أصبحت علامة 3KU معروفةً على نطاق واسع بين مستخدمي الطابعات ثلاثية الأبعاد وهواة هذه التقنية. ونوفر مجموعةً كاملةً من الدعم الفني تشمل الطابعات ثلاثية الأبعاد الخاصة بصب المجوهرات، ومعالجة القطع بعد الطباعة، وتقنيات الصب، بالإضافة إلى ضمان مدى الحياة. كما نقدّم خدمات تكنولوجية احترافية وخدمات تخصيص لحل مشكلات الطباعة والصب في مختلف المجالات.

وتستند طابعاتنا إلى تصميمٍ وأساسٍ هيكليٍّ أصليٍّ، لكن الأهم من ذلك أن فريقنا المتميز من الباحثين يستخدمها في مجال صب المجوهرات ثلاثية الأبعاد، مثل الصب السني وتلبيسات الأسنان، وصب المجوهرات، ومجموعات التجميع المنزلية (Garage Kits)، والقوالب الدقيقة، وغيرها. ويمكنك طلب عيّنات مجانية. ونحن نستطيع طباعة ملفات STL على طابعاتنا وإظهار كيفية عملها والنتائج التي تُحقّقها قبل الشراء.

منذ أن طوّر مؤسسنا أول طابعة ثلاثية الأبعاد لصبّ المجوهرات، عمل مع طابعات ثلاثية الأبعاد تدرّجياً من تقنية FDM إلى تقنيتي DLP وSLA. وهو يؤمن بأن «التقنية الثلاثية الأبعاد ستُحدث ثورةً جديدةً في القطاع الصناعي». ونسعى جاهدين لتقديم دعمٍ أوسعَ للقضايا الفنية وخدمات ما بعد البيع لأولئك الذين يحبون الطابعات الثلاثية الأبعاد، والذين قدّموا لنا دعماً قوياً! ونوفر خدمةً لطيفةً وسريعة الاستجابة لاحتياجات السوق.

تُستخدم طابعات الـ3D الخاصة بصبّ المجوهرات في مختلف القطاعات، ومنها: صناعة المجوهرات، والمعابد، وطب الأسنان، والخزف، وغيرها. ولدينا خدمات مخصصة ممتازة تشمل: التصميم البصري والملامس (الشكل والمظهر)، ووضع شعارات مخصصة، وتصميم البرمجيات، وإضافة وظائف إضافية، وتغليف مخصص. ونوفر لعملائنا أفضل طابعات ثلاثية الأبعاد مقابل المال الذي يدفعونه، وهي طابعاتٌ تتميّز بجودتها العالية، ووظائفها العملية، وكفاءتها التشغيلية.

حقوق النسخ © شركة شنتشن 3KU للتكنولوجيا والعلوم المحدودة. جميع الحقوق محفوظة سياسة الخصوصية المدونة