You ever heard of SLA, DLP and LCD printing? So these are the different ways in which we can produce a 3D object inside the Speaker by creating them on any designing tool. And each uses light in its own unique way to convert a liquid into solid form - transforming our ideas from thoughts into three-dimensional things!

SLA: Stereolithography This process involves the curing of liquid known as resin by a special laser. It actually occurs layer by layer, in which the printer essentially compiles an object one thin slice at a time. SLA PrintingOne major benefit of SLA printing is the capacity to create very detailed and smooth objects, which comes in handy for miniatures or delicate designs. But, this approach often takes a long time to complete an application. Lastly, making a video of the water feature can be costly in and of itself because materials needed to create it are expensive as well.

Alright, let me touch DLP — Digital Light Processing. How this works is wonky. DLP replaces laser with a projector to project the light onto liquid resin in a vat. Rather speedier than SLA, DLP utilizes a light source (acting much like a slide projector) to cause photo-initiated polymerization of liquid resin. This way you can have your objects produced faster! DLP can also produce intricate forms but might not be as exact in other cases prefer SLA. Also, bear in mind that the projector used for DLP can burn out over time and will need replacing which could end up being an extra cost.

Next up is LCD printing. It has an LCD screen that precisely blocks light to create a layer and prevails over the liquid resin, as used by any other method (of this kind), with its own subtleties. It is known as the fastest method of LCD printing among three. A lot of users also- find it very attractive, because they can generate a fairly precise shape quickly. Although it might not have the same level of detail as SLA methods, LCD screens can sometimes cost more than those other techniques. The second point is that, although it provides speed. It may not really be suited to you based on your requirements of what might be best for you or the workflow in general.

Well, what kind of 3D printing do you need? But at the end of this line, it really matters what are you going to build. SLA would be a better option if you are seeking for objects that have high detail and smoothness which does not print well with FDM. In contrast, if you are looking for something but fast and not quite as accurate then DLP may be a better choice. If you need a quick and inexpensive solution, then LCD might be your best option. Consider what is most critical to your project.

A few key things to keep in mind if you are keen on experimenting with 3D printing. The first thing is to have a software in which you will design the 3D object. This is the software that allows you to design your printable model. Once you've prepared your design, select the 3D printing process and material. They may or not have same properties based on the materials used. For instance, some material may be stronger than other while others might have more flexibility. You may want to choose one that suits your project. At last, you will require a 3D printer to convert your design into tangible entity which can be held!

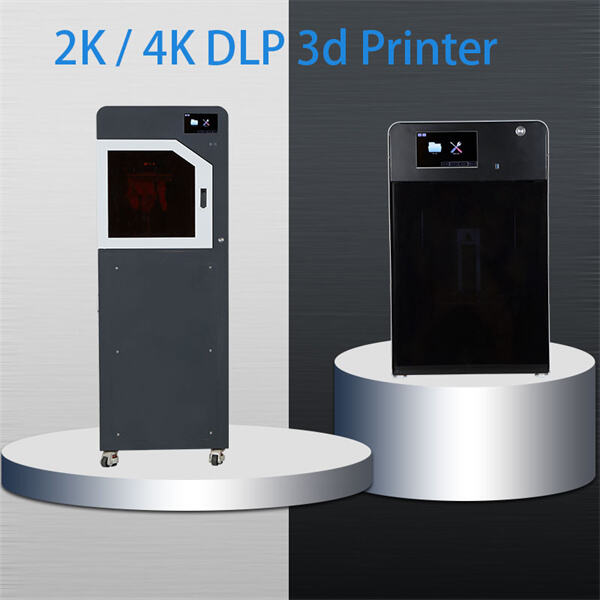

Based on a unique design and structure, especially our sla dlp lcd, our printers are used in various industries, including Dental cast and crown, Jewelry cast, Garage Kit, Precise Molding, ect. Samples are free. We can print STL files on our printers, and show you how they operate and the outcomes before you buy.

Our printers have been employed in many industries including jewelry, Temples Dentals, Ceramics and more. Our sla dlp lcd are ideal. We provide a variety of custom services, such as packaging design and software, branding, packaging and many more. We provide our clients the best priced 3d printers that are of good quality, practical utility and high-efficiency.

The sla dlp lcd of our company is working on 3D printers since 2012, starting with FDM, DLP, SLA. He believes that "3d technology is going to lead another revolution in the industrial sector". We strive to offer more service and technical assistance to 3D printer enthusiasts who believe in us strongly! We have the best priced tower packaging. We provide courteous service, and we can respond quickly to market changes.

Shenzhen 3KU Technology and Science Co. LTD was founded in 2014. In just a few short months, 3KU has become a household name for 3d printer users and fans. We provide a complete range of technical support that includes sla dlp lcd, post-processing, casting techniques, and a lifetime warranty. We provide professional technology and customizing services to solve the printing and casting problems in different areas.

Copyright © Shenzhen 3KU Technology and Science Co., LTD. All Rights Reserved Privacy Policy Blog