We've been making pottery for thousands of years. The art of ceramics involves the shaping and hardening of clay to produce objects such as vases, bowls, jugs or cups. People have been making pottery for a very long time; this is done with the use of either just hands or by using a potter's wheel. This was a very timely laborious process that required great skill. The artists would spend years in training so that they could craft a pattern just right. However, a cool new tool is changing the way pottery can be produced: 3D printing!

Previously, creating pots took many steps. An artist would prepare the clay, shape it on a pottery wheel and fire to harden. This entire, drawn out process might take hours - even days. Even better, with 3D printing you can make pottery much quicker than any wheel could allow. People no longer shape their pottery with hands and wheels, they design it on a computer and print out the sculpture using a 3D printer. Which makes pottery-making possible for anyone without a prior practice of several years.

But, 3D printed pottery is unique as it brings together the world of digital age technology in a classical approach to art. Special software allows a designer to create an object model using their computer. The 3D printer can make that a reality within a very short space of time once they have the design ready. It is completely unlike the history of pottery making!

This new way also enables designs that are too complex to create by hand. 3D printing can produce stunning patterns, complex shapes and smooth surfaces that will make every piece of 3D printed pottery look incredible For example. This way, artists can now create things that they never could before (which makes their work even more exclusive and fun).

The world of pottery is not outside the 3D printing circle and it has significantly changed how we make this ancient industry. Well now many more people can make their own pottery without having access to a wheel and kiln. For example, instead of paying for expensive tools they can use computer programs and a 3d printer to make their products. This opens up pottery to artists, hobbyists or virtually anyone interested in crafting - regardless of their level.

It makes the world of pottery more wholesome and approachable. Those who may have never even considered that they could enjoy the making of pottery are discovering it. There is an endless list of ways to be creative, and something for everybody here at Ancestry.com.

Anyone can Become a Potter with 3D printing In the workshop, you can design and print your own pottery pieces using a little imagination (and some highly specialized tools). Which means you can create as many designs as you like without having to worry about how much clay is, or even quality over quantity because it just takes so damn long?

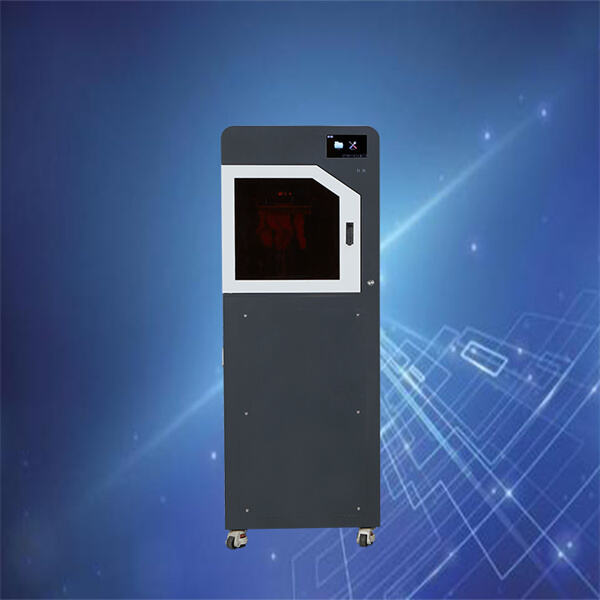

3d printed pottery founder of our company has been working on 3D printers since 2012, beginning with FDM, DLP, SLA. He believes that "3d technology will lead another industrial revolution"! We try our best to provide better service and technical assistance to 3D printer lovers, who we support and are steadfastly in our support! We provide the most competitive tower packaging. We offer a friendly service and can react quickly to market shifts.

Shenzhen 3KU Technology and Science Co. LTD was established in 2014. Within a few years of marketing and development, our brand 3KU is well-known to 3d printer 3d printed pottery and users. We offer a complete technical support, printing technology, after casting processes, and a lifetime warranty. We provide professional technology and a customized service to help with casting and printing issues across different fields.

Based on a distinctive design and construction, notably our top research team our 3d printed pottery are used in various industries, including Dental cast and crown, Jewelry cast, Garage Kit, Precise Molding, ect. We offer free samples. You can provide us with STL files and we print with our printers to show how it works and what the results look before you purchase.

Our printers have been employed in many industries including jewelry, Temples Dentals, Ceramics and more. Our 3d printed pottery are ideal. We provide a variety of custom services, such as packaging design and software, branding, packaging and many more. We provide our clients the best priced 3d printers that are of good quality, practical utility and high-efficiency.

Copyright © Shenzhen 3KU Technology and Science Co., LTD. All Rights Reserved Privacy Policy Blog